bob w

Still crazy after all these years!

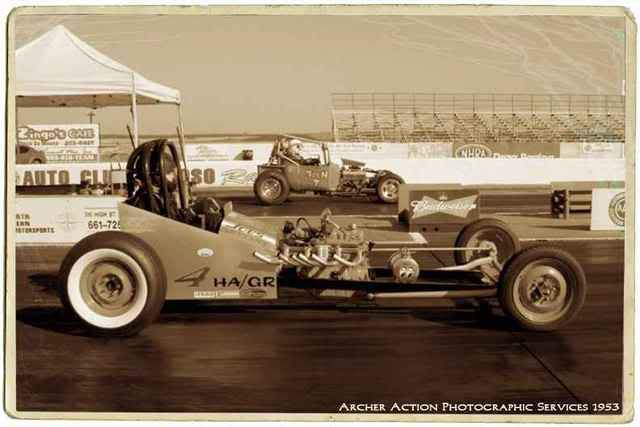

Over on the H--B site there is a sub-site devoted to building and racing dragsters that are patterned after the very first "rail jobs" from the mid 1950's. Here is a pic of one owned and build by a California guy by the name of Rocky. I intend to pattern mine after his. (He doesn't mind).