Make a plywood template you can put vertically up the body at the edge of the door or on the door edge itself. It will go from rocker to roof top. Then you can just set it against the panel to see if you are close. You can also re-use it for the other side so it is the same. You may have to make a front door jamb template and a rear door jamb template as the curve isn't always the same.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1933 chevy tudor sedan aka Project Copper Tone!

- Thread starter endicott_jb

- Start date

Help Support Rat Rods Rule:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

endicott_jb

Well-known member

I already did the door jams but thanks for the plywood idea. I think some 1/4" plywood is in my near distant future. Plus it gives me a reason to pickup a jig saw.

endicott_jb

Well-known member

Haha!!!! Got my figment issues solved. Turns out most of my problems was the lower forward brace for the door jam. Hopefully the passenger side won't be as big of a p.i.t.a. And I also figured out how I'm gonna do my latches. Seeing as I'm not running glass, reaching in to open the door isn't an issue so I'm just gonna use the inside door handles with the stock latches. Right now I have the latches soaking in penetrating fluid to try and free them up a bit. If I'm not too tired tomorrow after work I'll be tackling the latches and get everything working how it should. Anyhow, here's a few pictures of today's progress for y'all. Feel free to comment.

endicott_jb

Well-known member

endicott_jb

Well-known member

Looks like I won't be doing anything with the car until next week maybe. We've got a really cold spell coming through. Right now it's at -17 degrees and ain't sposed to get above zero until next week sometime. Even with the turbo heater pointed directly at me, it's too dern cold to do much.

endicott_jb

Well-known member

Thanks Sam. I'm trying to use as much of the original parts as possible. Just seams to make things simpler.

junker39

Well-known member

Looks like I won't be doing anything with the car until next week maybe. We've got a really cold spell coming through. Right now it's at -17 degrees and ain't sposed to get above zero until next week sometime. Even with the turbo heater pointed directly at me, it's too dern cold to do much.

And I thought it was cold here at 39. I may just put my shorts and tee shirt on and go outside. Wow. -17??

zzrodder

It ain't grey hair, it's chrome!

I guess those tin walls don't do much for holding heat in  , more like a freezer! You deserve kudos for keeping on the job in those temps. We don't have it so cold here in BC, only -17 C ( about 0 F ) tonight

, more like a freezer! You deserve kudos for keeping on the job in those temps. We don't have it so cold here in BC, only -17 C ( about 0 F ) tonight  . The body framing work is coming along great.

. The body framing work is coming along great.

BlueNorther

Well-known member

-12f or -24c here right now in central MN

endicott_jb

Well-known member

Yeah, the shop turns into a freezer especially at night when the sun goes down. My family is all in CA and they're whining about how cold it is and it's in the 40s. They wouldn't be able to survive up here lol. I did notice that there aren't nearly as many Canadian plates down here since the storm came in. I think the cold even scared you guys away for a while.

endicott_jb

Well-known member

Well, I decided to trudge the cold and got quite a bit done today. Te outer framework for the passenger side door is done. I'm gonna mount it to the body before I put the secondary bracing in and check for fitment. This door is really rough compared to the drivers so I haveta fix a few cracks in the skin. I'll take pictures once it's mounted.

endicott_jb

Well-known member

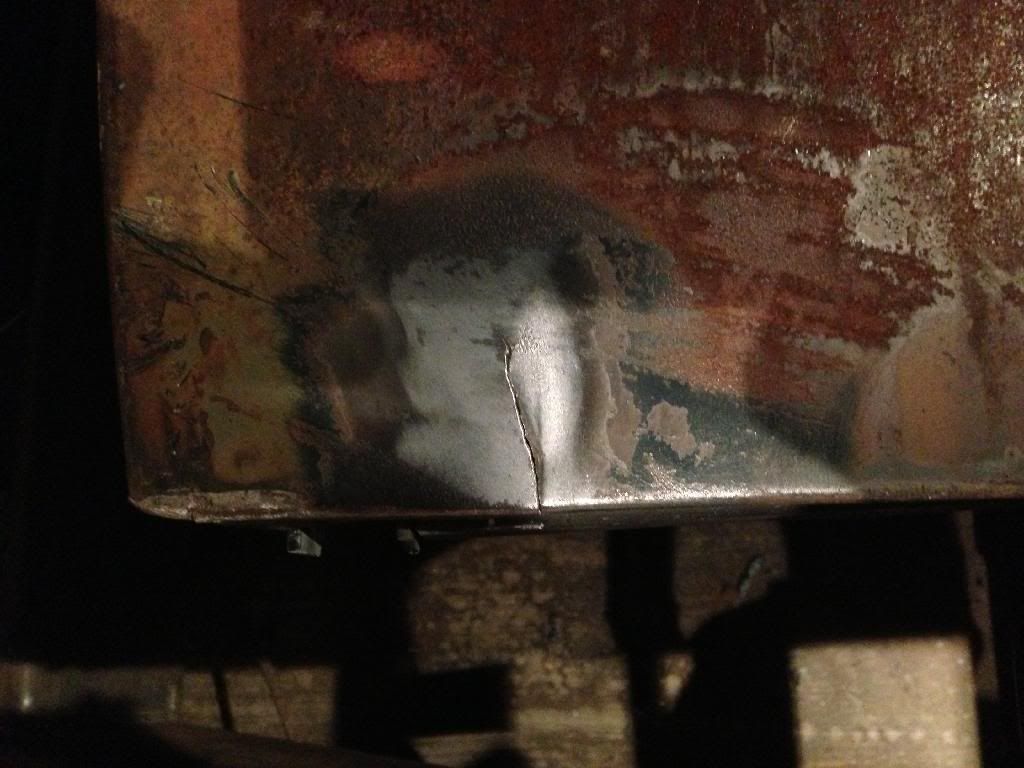

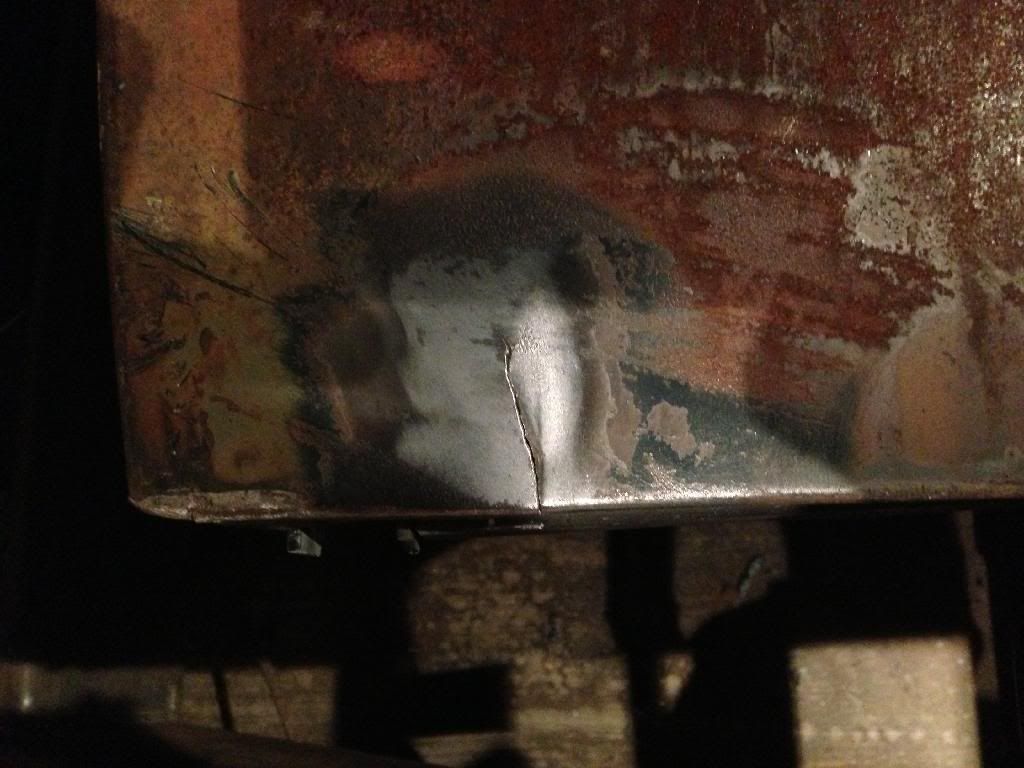

So before mounting the door I needed to fix the cracks in the door skin. So, I drilled the ends of the cracks to keep them from cracking anymore. Then I proceeded to spot weld them up and then found them off using an 80 grit flap disc. I gotta say, flap discs are by far my favorite tools when it comes to grinding down welds.

I'll try to get the door mounted tomorrow but I can't make any promises lol.hopefully I can get it finished up so I can drop the body back on the frame and make my body mounts.

I'll try to get the door mounted tomorrow but I can't make any promises lol.hopefully I can get it finished up so I can drop the body back on the frame and make my body mounts.

endicott_jb

Well-known member

Got more of the passengers side door done today. Got it mounted, I have fitment issues but it's close enough to look okay from about ten feet lol. Door latches are in and turns out the handle was a bit frozen. So, pulled the handle off, it's stripped out so I have to find another and for now, I'll just do the classic vise grip door handle. The odds are, I'll have to replace the whole assembly some day but hell, if it work, why touch it? Next on the list is to get the lower panel spot welded to the frame work and then screw the forward jamb piece into place. This cold is making it a bit hard to work as my feet freeze after about 2 hours and if I put thicker socks on they just sweat until the freeze so it's a lose lose situation. After I get the body finished up, I haveta readjust the transmission mount so that it's more centered. I don't know what I was thinking when I welded it in but thank god for drills and cut off wheels. Hopefully by the end of this weekend I'll be able to have the body back on the frame and work on the mounts. I have a few bias ply tires I'll be cutting circles out of to use as cushions for the mounts. I think it'll work fine. Seeing how the original mounts just had strips of canvas and leather between the pieces. Anyhow, I'll post some pictures when I get around to taking them lol.

earthman

Fascinated by rolling objects!

And when you are not driving it you can use it as a vault.  Great thread! Thanks.

Great thread! Thanks.

endicott_jb

Well-known member

Thanks guys. I just hope that it turns out as cool as I want it to. There's a lot of little piddly stuff I still gotta take care of on the frame and front end. I keep bouncing around, which is really against my OCD, but it's to keep me going.

endicott_jb

Well-known member

earthman

Fascinated by rolling objects!

MercuryMac

Builder Junky!

Whoa jb you're doing the right thing, I think. Mock up everything before you weld it in solid, and this includes the seats, steering wheel, pedals, and gearshift. If you need to move something, now is the time to find out. So you did the right thing. As far as the car noises go, I'll bet all the cool guys do that so that too, has to be right, Right!

Keep on tinkering.

Keep on tinkering.