jmlcolorado

Well-known member

Man this thing is cool. And 27 MPG!! Wow, that's incredible. I back tracked the thread a little and don't think I saw what you did to the windshield. Did you find a modern car with a good curve for it? Have fun with it, glad to see it on the road.

Well, ya caught me.

I don't have glass in the front yet. I installed lexan temporally to get the truck to the last couple shows of the season.

Come to find out that this stuff is a static machine. And I live on 2 miles of dirt road before I see pavement so every time I leave t gets coated inside and out with dust.

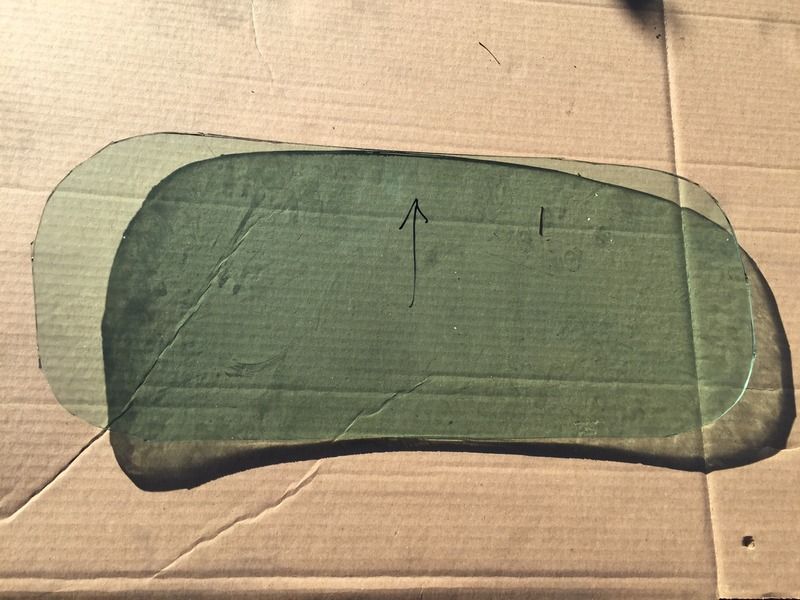

Ironically enough, yesterday I picked up the donor glass for the cause.

These are two windshields out of a 1986 Saab 900.

I had made a template with the radius quite some time ago and went to the junk yard on a search for some cars with the right radius. I found 2. 1972 Datsun 280z and the Saab.

The Datsun glass was pretty difficult to come by, so the Saab it is.

My buddy is a glass guy by trade but he's used to dealing with custom shower enclosures that are typically flat. However, he does have ALOT of experience in cutting glass so I've solicited his assistance in a couple weeks to cut these down to the right size.

I got these for $120 each, so I won't be heartbroken if we break one or two in the process.

The glass for the international came in at the tube of $500 before shipping. I couldn't stomach the chance of breaking one of those trying to get two pieces out of it so I thought this might be a better route.

We shall see.

I'll post up progress on the glass once we start going to town on them.