Nash Nick

Member

Well I just joined here and figure I might as well get a build thread started for my car. Its is a '63 AMC Rambler American. I bought the car from my buddy's brother about a year and a half ago and have been working on it ever since!

A Little Back Story:

When I was young, my father and I restored a 1954 Chevy 210 2 door sedan together. It was a 3 speed car with the 115 "Blue Flame". I loved that car but sadly he had to sell it before I could even drive it on my own (I drove it a few times when I had my permit though!). Ever since I've wanted a 3 on the tree car of my own. The Rambler had been sitting at my buddy's shop for a while and I always told him that if/when his brother sells it, I would buy it. After a year or 2 I got a call, the price was right, and it was mine!

Here's the car the day I bought it:

Perfectly good chrome painted black! Fixed that quickly!

Fixed that quickly!

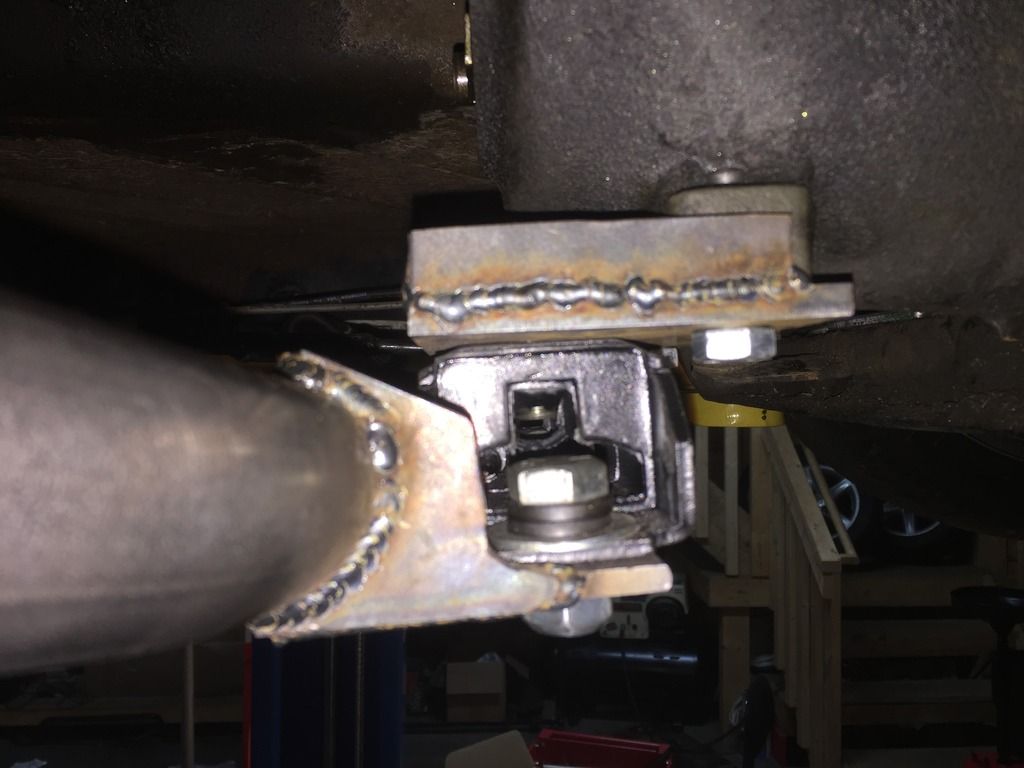

I had a lot of different ideas for the car at that point but I knew I wanted to bag it and I knew that the original patina was staying as is. I decided against a bag on leaf setup (the Americans aren't torque tube) and decided to give a universal 4 link kit a shot. With these cars being unibody it was pretty awful to do and it still needs some work but over the summer of 2014 I got the 4 link in and over the winter I made brackets to bag the front trunnions. Got a set of Jeep wheels on the cheap from my girl's dad and the car wasn't looking half bad!

I made my own air management using a micro controller too! Threw in some new carpet and made some door panels also. Drove the car a bit over the summer and got a lot of positive comments which is always nice! The poor flathead was burning a lot of oil though and after doing some research and such I realized it wasn't really worth rebuilding which puts me where I am now.

The Build:

I did a lot of reading about swaps in these cars. People claim that 200ci Ford 6's are common swaps because they are small like the AMC/Nash 196's but I couldn't find a whole lot of info from people who had actually done the swap. I did find that the T96 trans is basically the same as the Ford 2.77 "crash box" 3 speed and that with a 2.77 bell housing my t96 would bolt up to the 200, so I found a nice 200 and a 2.77 with a bell housing on Craigslist and bought them!

Bye flathead!

The 196 and the 200 side by side.

Turns out the input shafts are different, the T96 input shaft is longer and fatter at the end. Great. Well I was planning on rebuilding the trans anyway so apart it went to rebuild and machine the input shaft to match the 2.77 I now have! I still need to sort out the engine and trans mounting. Also the 200's are typically front/mid sump while the 196 is rear sump to clear the steering so I'll need to fab up a pan before I can even test fit the new engine but I'm excited to have more power and more reliability!

A T96 in 96 pieces (ok maybe like 12 but you get the point )

)

Another side project for this winter is new management and an 8 valve air setup vs the 4 that is in it now. I have been working on the new management that has more presets and better functionality as well as an LCD display...

in the stock radio bezel! Also made one for my buddy's '64 Belair! (his is on the left) Well anyway let me know what you all think and I'll be updating this regularly as I move forward with my plans!

A Little Back Story:

When I was young, my father and I restored a 1954 Chevy 210 2 door sedan together. It was a 3 speed car with the 115 "Blue Flame". I loved that car but sadly he had to sell it before I could even drive it on my own (I drove it a few times when I had my permit though!). Ever since I've wanted a 3 on the tree car of my own. The Rambler had been sitting at my buddy's shop for a while and I always told him that if/when his brother sells it, I would buy it. After a year or 2 I got a call, the price was right, and it was mine!

Here's the car the day I bought it:

Perfectly good chrome painted black!

I had a lot of different ideas for the car at that point but I knew I wanted to bag it and I knew that the original patina was staying as is. I decided against a bag on leaf setup (the Americans aren't torque tube) and decided to give a universal 4 link kit a shot. With these cars being unibody it was pretty awful to do and it still needs some work but over the summer of 2014 I got the 4 link in and over the winter I made brackets to bag the front trunnions. Got a set of Jeep wheels on the cheap from my girl's dad and the car wasn't looking half bad!

I made my own air management using a micro controller too! Threw in some new carpet and made some door panels also. Drove the car a bit over the summer and got a lot of positive comments which is always nice! The poor flathead was burning a lot of oil though and after doing some research and such I realized it wasn't really worth rebuilding which puts me where I am now.

The Build:

I did a lot of reading about swaps in these cars. People claim that 200ci Ford 6's are common swaps because they are small like the AMC/Nash 196's but I couldn't find a whole lot of info from people who had actually done the swap. I did find that the T96 trans is basically the same as the Ford 2.77 "crash box" 3 speed and that with a 2.77 bell housing my t96 would bolt up to the 200, so I found a nice 200 and a 2.77 with a bell housing on Craigslist and bought them!

Bye flathead!

The 196 and the 200 side by side.

Turns out the input shafts are different, the T96 input shaft is longer and fatter at the end. Great. Well I was planning on rebuilding the trans anyway so apart it went to rebuild and machine the input shaft to match the 2.77 I now have! I still need to sort out the engine and trans mounting. Also the 200's are typically front/mid sump while the 196 is rear sump to clear the steering so I'll need to fab up a pan before I can even test fit the new engine but I'm excited to have more power and more reliability!

A T96 in 96 pieces (ok maybe like 12 but you get the point

Another side project for this winter is new management and an 8 valve air setup vs the 4 that is in it now. I have been working on the new management that has more presets and better functionality as well as an LCD display...

in the stock radio bezel! Also made one for my buddy's '64 Belair! (his is on the left) Well anyway let me know what you all think and I'll be updating this regularly as I move forward with my plans!