cornfield customs

Well-known member

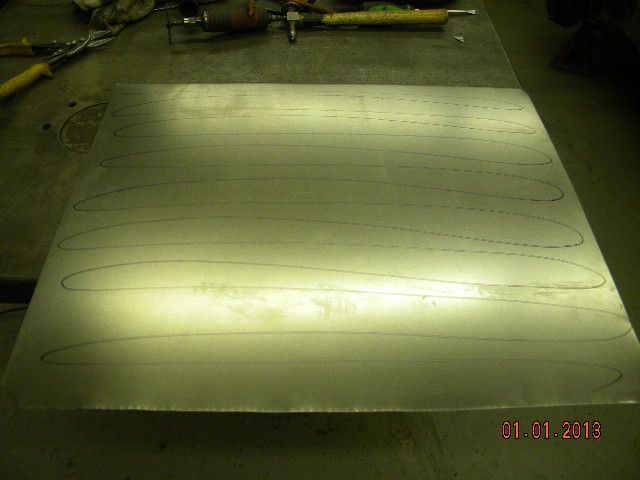

all the sheet steel i use in the shop is 18 gauge

That door repair is ridiculous. I am now going to go and find every single bit of metalwork I have done in my life, push it all into a big hole and bury it.

Right. After your last post I am now going to have to dig all that stuff back up, burn it, and then bury it again.

Beautiful work.

Enter your email address to join: