cornfield customs

Well-known member

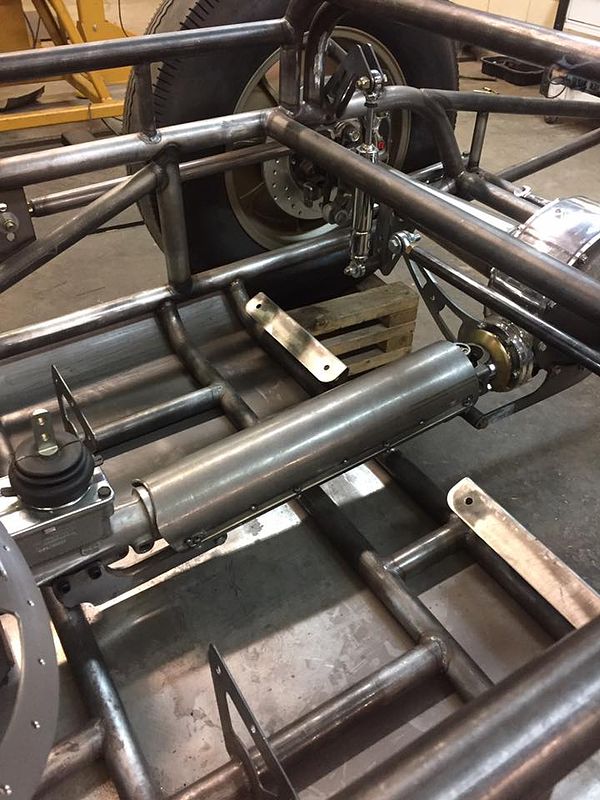

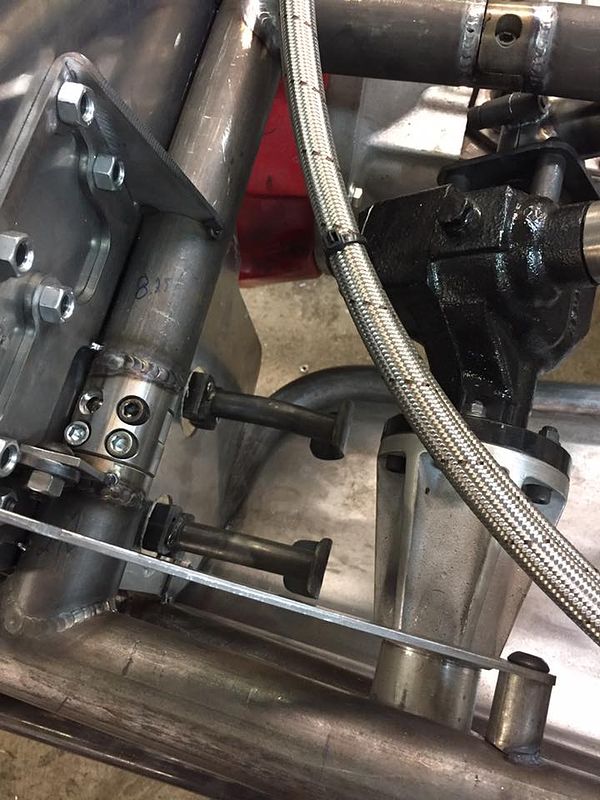

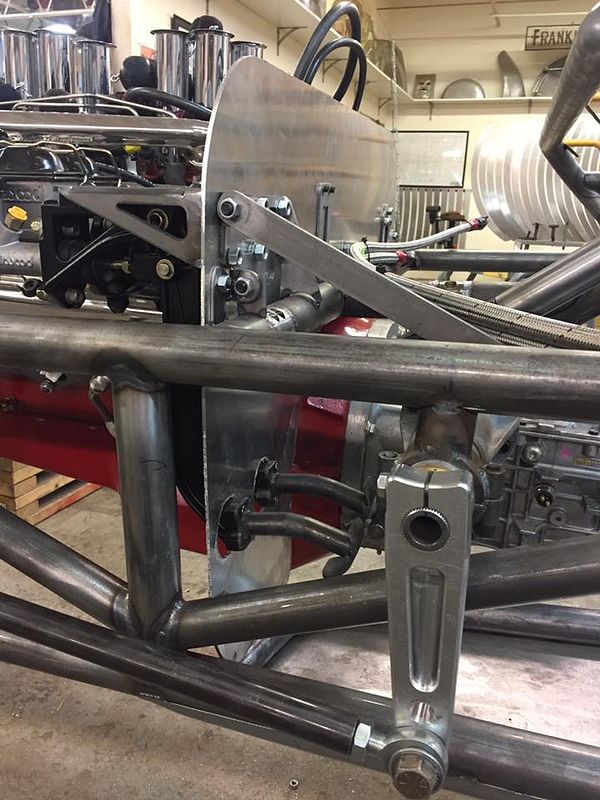

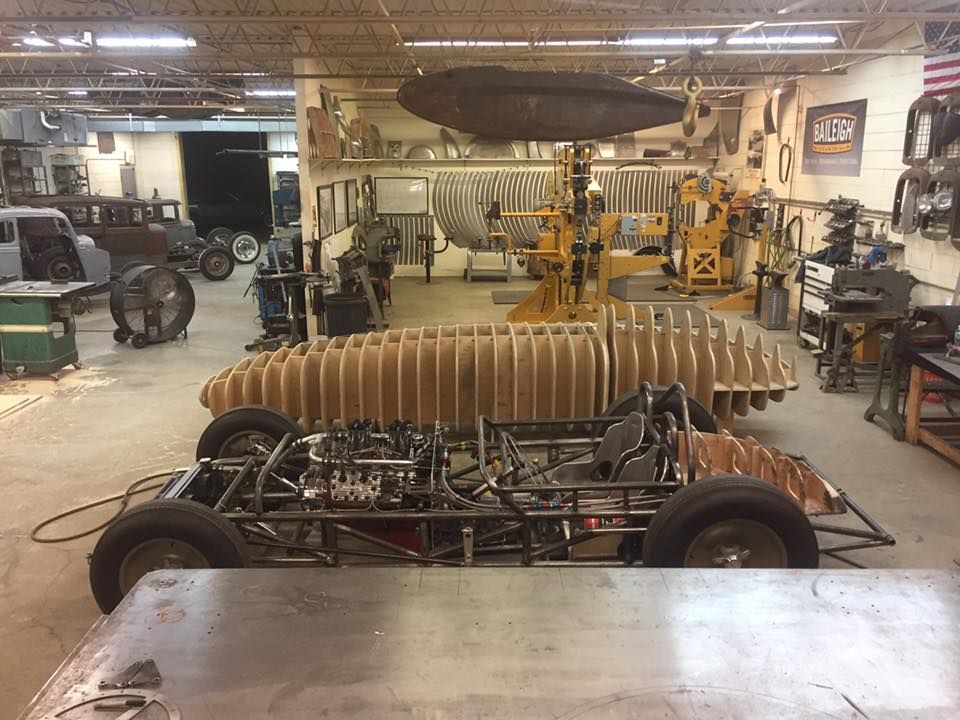

Another project we started not to long ago (November 27 2016) is this AJ Watson styled Indy roadster project. It is closely based on the watson, just widened 4 " in the front, 8" in the rear and stretched 10' in the cockpit to make it a two seater for the street. we are building the full chassis, and body in house. i will keep the typing to a minimum since everyone likes the pics more than reading all my BS lol

day 1 Nov 27 2016. set up the axles at what the customer had requested 96" wheel base, stock to a watson. we ended up stretching it 10" after this point when the customer could see how little room would be in the cock pit at 96"

then things progressed, sorry some of the pics may be a little out of order. i didnt take a ton and they got imported in a weird order.

and fast forward a couple weeks, didnt take a ton of pics of the process

day 1 Nov 27 2016. set up the axles at what the customer had requested 96" wheel base, stock to a watson. we ended up stretching it 10" after this point when the customer could see how little room would be in the cock pit at 96"

then things progressed, sorry some of the pics may be a little out of order. i didnt take a ton and they got imported in a weird order.

and fast forward a couple weeks, didnt take a ton of pics of the process