Fan Shroud

While being frustrated with the brakes and needing something to to work on that would provide results I decided to build a quick and easy fan shroud.

Well, it didn't work out that way, but next time it will go a lot quicker and easier. I'll explain what I did and what I should have done.

I went to Home depot and got a gallon of resin, some fiberglass mat and fiberglass cloth. I also got some stretchy material from the thrift store.

What I should have done is gone to Sticky Stuff ( about 40 miles from my house) and gotten the resin he recommended and some heavier mat. The HD stuff is probably good for fiberglass repairs, but not so good for laying up panels. Bottom cloth ( the stuff they put on the bottom of couches) or speaker cloth is thinner and smoother and would save a bunch of time and material.

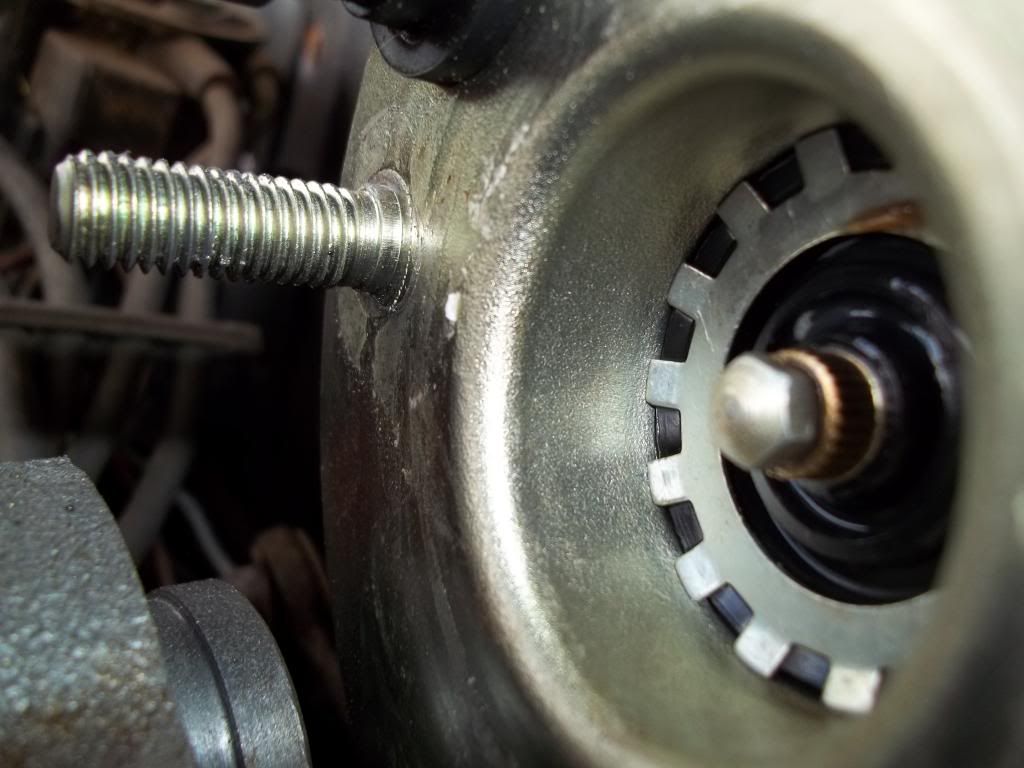

I cut a piece of plywood (3/4" mdf would have been better, but I didn't have any) the size of the radiator support, which is where I wanted to mount the shroud. My fan is 19" so I looked for something 20" and found a 20" flywheel that was 1 1/4" solid cat iron. I drew a circle on the plywood where the fan is in relation to the radiator support. Centered the flywheel over the circle and shimmed it up. Since the engine is at a bit of an angle, the top is further away than the bottom. Then I covered the whole thing in aluminum grilling foil. (photo 1).

I cut some 3/8 x 3 the height of the shroud and a piece of box tube that would fit on the bottom. The fan comes to the top of the shroud so I didn't need anything there. The fleece was stretched and stapled to the plywood. Resin applied and the aluminum wrapped pieces were clamped in place. (photo 2).

Photo 3 shows the big mistake. I should have turned it over and put the mat on the inside, instead of trying to build the thickness on the outside. After a couple layers of mat - the shape was pretty much lost. I sanded; then used long strand filler to smooth it up (photo 4). Sanded a lot more; then used short strand filler. Sanded, then filler. Then sanded some more. Another 10 hours of body work would get it nice instead of "OK painted flat black if you don't look real hard".

A hole saw cut for the hoses. A vibrating multi-tool worked really well for the cuts.(photo 5)

Then I glassed the inside (photo 6). I made the mounting holes really big and painted it.