I built one for my rock crawler toyota pickup. Gota rember, kegs are not alum, they are stainless steel, makes welding them easier.

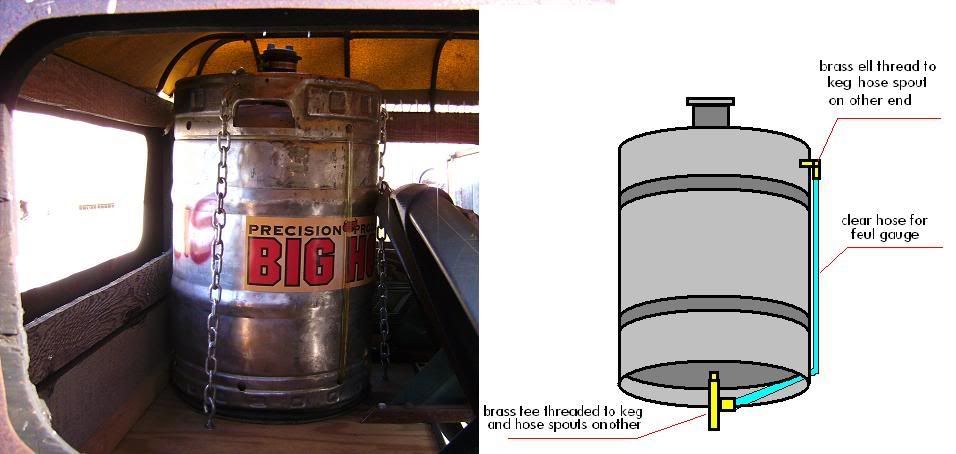

It works great, I wish I had run a piece of clear tube down the outside as a fuel guage. (or hooked up a sender)

It has a piece of 4x4 box tube cut into the botom as a catch/windage pan, the filler is just an old gas fillerneck that we welded on after (completly destroying) hole sawing the top of the tank. I pulled all the guts out of the keg bung, and caped it with a piece of flat stainless. I needed 3 lines, one send, one return and vent, I used stainless torch tubing I got from a budy who is a torch repair guy. It sucked to bend beacuse its so thick, but we got it to work.