Willowbilly3

A *real* tin magnet

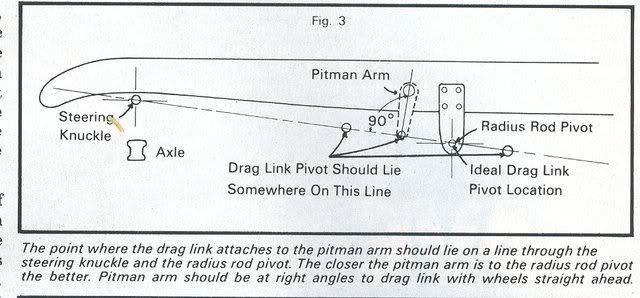

OK, now I know that a bunch of hotrods have ill sorted steering. I spent all day yesterday working on my pitman/drag link/steering arm. Just to have my tierod anywhere near level, this is how the steering arm came out. I really don't need advice on how strong it isn't, this is just a mockup. Basically the way the math works out to have the steering box and the axle both on the stops at the same time, the pitman arm is about 2 inches shorter than the steering arm (measured from the back of the spindle where it bolts on) Sooo, in order to not have like a 5 inch long pitman arm and a steep angle on the drag link, this is the best compromise I came up with, a steering arm 13 inches long with a 4 inch rise.

I see a lot of long pitman arms and now I know those steering boxes have to be hitting the stops before the axle, or else they must be like 40:1

I could move my box down a couple inches which would require redoing several days of work. I'm about ready to push it out in the weeds.

Any suggestions?

I see a lot of long pitman arms and now I know those steering boxes have to be hitting the stops before the axle, or else they must be like 40:1

I could move my box down a couple inches which would require redoing several days of work. I'm about ready to push it out in the weeds.

Any suggestions?