kelseydum

Well-known member

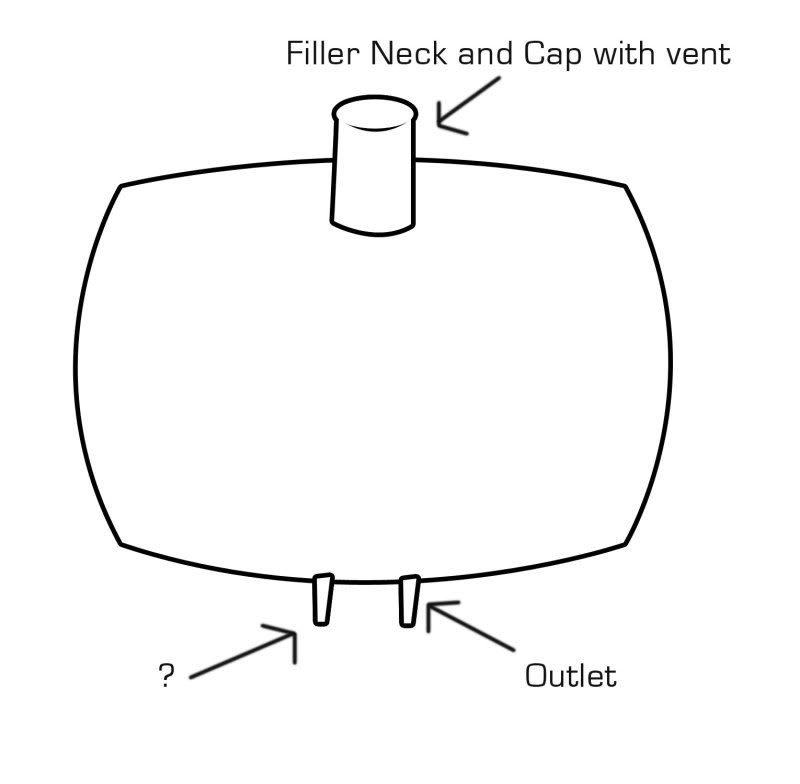

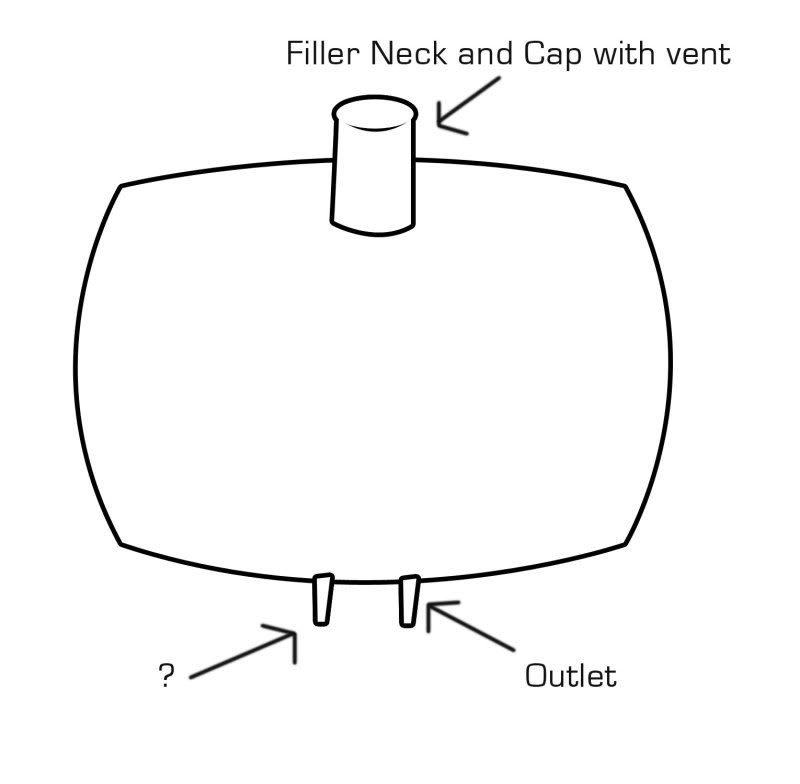

Most of you know I'm new to this and this is my first keg gas tank. I know this is pretty simple, but I'm not quite understanding one thing. The drawings and pictures of keg tanks I've seen look something similar to this...

However, in doing research I noticed that a carbureted motor only needs an outlet and not a return... Is this correct? If so do I only need one hose fitting on the bottom? The cap will be vented so no need for an extra vent, and I'm just going to use a dipstick to check my fuel level.

On my list of items to get are:

1. My aluminum filler neck and vented cap.

2. 1 aluminum fitting for the outlet (goes on bottom of tank).

Also in just trying to understand things as a whole better I have one more "stupid" question. On the older motors the fuel pump connects to the motor instead of close to or in the gas tank on newer models. How does the fuel flow through the system? Does the fuel go from the tank to the fuel filter then to the carburetor? Is there some left over gas that isn't burned, and does that go back to the tank (hence needing a return line)? Like I said, I'm a little confused and really new to this so any help is appreciated. I've done a ton of research but can only find so much info.

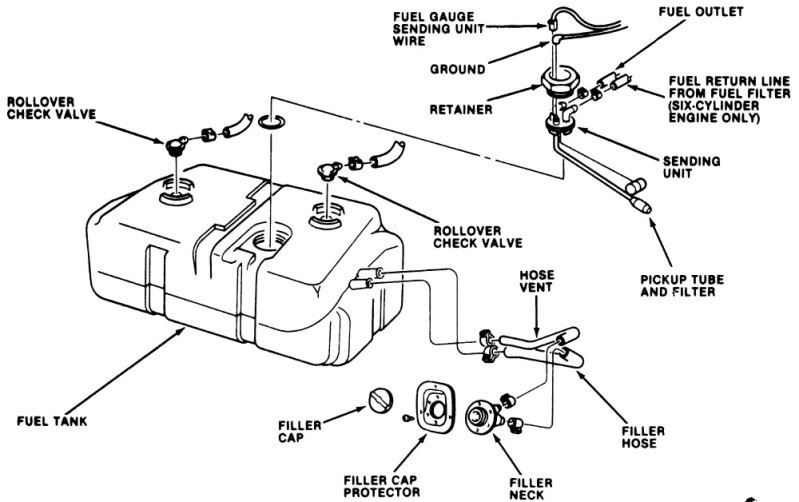

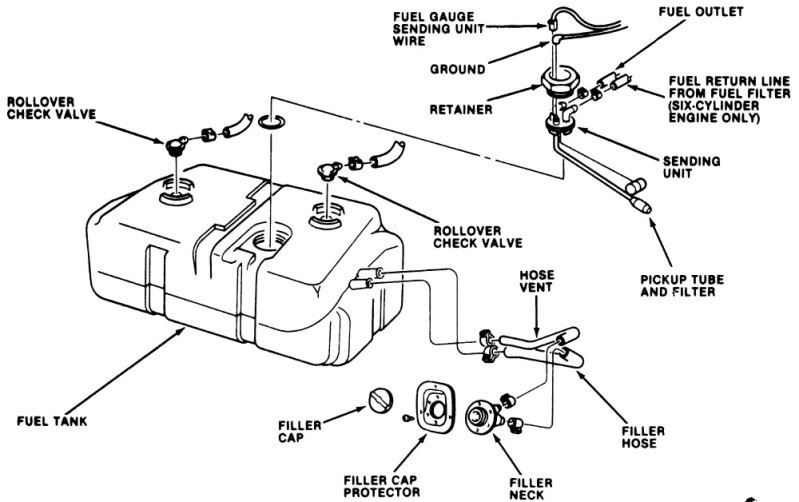

I found this pic that Bonehead (I think) posted, but is this for a fuel injected motor?

However, in doing research I noticed that a carbureted motor only needs an outlet and not a return... Is this correct? If so do I only need one hose fitting on the bottom? The cap will be vented so no need for an extra vent, and I'm just going to use a dipstick to check my fuel level.

On my list of items to get are:

1. My aluminum filler neck and vented cap.

2. 1 aluminum fitting for the outlet (goes on bottom of tank).

Also in just trying to understand things as a whole better I have one more "stupid" question. On the older motors the fuel pump connects to the motor instead of close to or in the gas tank on newer models. How does the fuel flow through the system? Does the fuel go from the tank to the fuel filter then to the carburetor? Is there some left over gas that isn't burned, and does that go back to the tank (hence needing a return line)? Like I said, I'm a little confused and really new to this so any help is appreciated. I've done a ton of research but can only find so much info.

I found this pic that Bonehead (I think) posted, but is this for a fuel injected motor?