It was suggested I make a Tech of what I did. Well, I won't call this a Tech, but it is what I did, the info I found, and what I learned.

(NOTE: some of the pictures in this Tech are borrowed from other sites, I will list links to those sites when I go over where I got my info)

Wrapping was done on ships wheels and railings for grip, called Coxcomb.

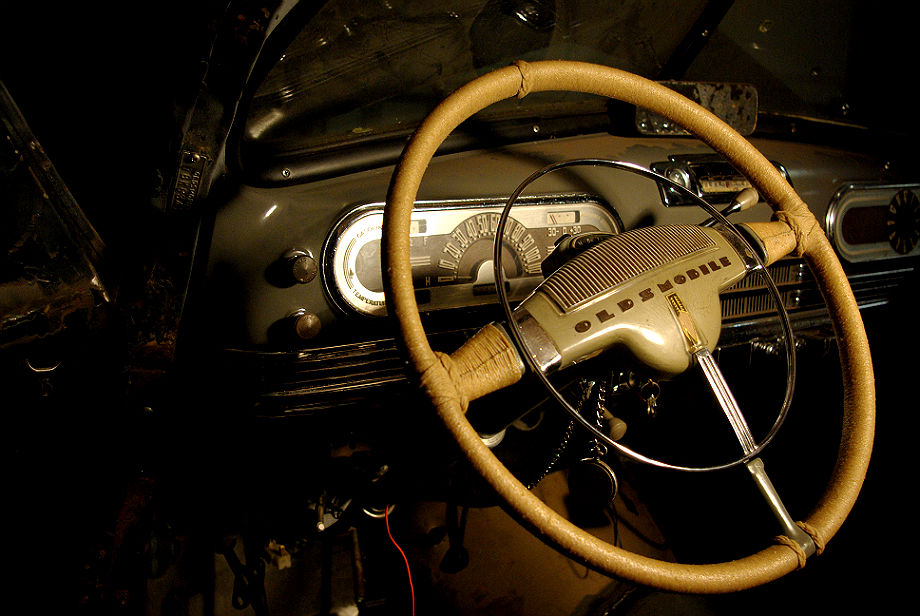

This is a pic of my finished wheel.

Here are a couple close ups of the T.

What I did:

First I filled the cracks with filler and smoothed it and spray bombed it.

For string I went through about 400ft of cotton twisted string (not sure what size). I did a simple wrap on the rim starting at the thin spoke. To start I simply laid the end of the string along the rim and started wrapping over it. Kept the string tight and cinched it up every few turns. When I got to the other spoke, I tied another string around the spoke and then wove the main string under on both sides most of the way across the spoke width and then tied it off. This is how I started and ended the large section also. Like this:

Next I wrapped the 2 spokes. This time I used a Simple Reversing Half Hitch (I'll get to what that is later). I started by tying off to the other string, then wrapping, and cinching up, but this time I used a needle. At the end, I just took the needle and stuffed the end of the string up under the wrap.

If you look, I had a lot of wheel still exposed at the T. So I came up with the !X! looking wrap to fill some of that space.

The last part were the Turkshead knots(I'll explain these more later too). Sailors would put one of these knots at the top of a ships wheel to easily find straight ahead. Mine is really there to cover a string splice and luckily the splice came right at the perfect spot. The bottom two are there to cover up the fact I didn't get the starts even. The other two spokes got them to finish covering up the exposed wheel. Those two were hard to get right - they were in a difficult spot, they were big, and they needed to cover up a wide area.

After all that I covered it all with 2 coats of Helmsman Spar Urethane - clear.

Somehow I caught on fire so I'll have to continue later...

(NOTE: some of the pictures in this Tech are borrowed from other sites, I will list links to those sites when I go over where I got my info)

Wrapping was done on ships wheels and railings for grip, called Coxcomb.

This is a pic of my finished wheel.

Here are a couple close ups of the T.

What I did:

First I filled the cracks with filler and smoothed it and spray bombed it.

For string I went through about 400ft of cotton twisted string (not sure what size). I did a simple wrap on the rim starting at the thin spoke. To start I simply laid the end of the string along the rim and started wrapping over it. Kept the string tight and cinched it up every few turns. When I got to the other spoke, I tied another string around the spoke and then wove the main string under on both sides most of the way across the spoke width and then tied it off. This is how I started and ended the large section also. Like this:

Next I wrapped the 2 spokes. This time I used a Simple Reversing Half Hitch (I'll get to what that is later). I started by tying off to the other string, then wrapping, and cinching up, but this time I used a needle. At the end, I just took the needle and stuffed the end of the string up under the wrap.

If you look, I had a lot of wheel still exposed at the T. So I came up with the !X! looking wrap to fill some of that space.

The last part were the Turkshead knots(I'll explain these more later too). Sailors would put one of these knots at the top of a ships wheel to easily find straight ahead. Mine is really there to cover a string splice and luckily the splice came right at the perfect spot. The bottom two are there to cover up the fact I didn't get the starts even. The other two spokes got them to finish covering up the exposed wheel. Those two were hard to get right - they were in a difficult spot, they were big, and they needed to cover up a wide area.

After all that I covered it all with 2 coats of Helmsman Spar Urethane - clear.

Somehow I caught on fire so I'll have to continue later...

Last edited: