cornfield customs

Well-known member

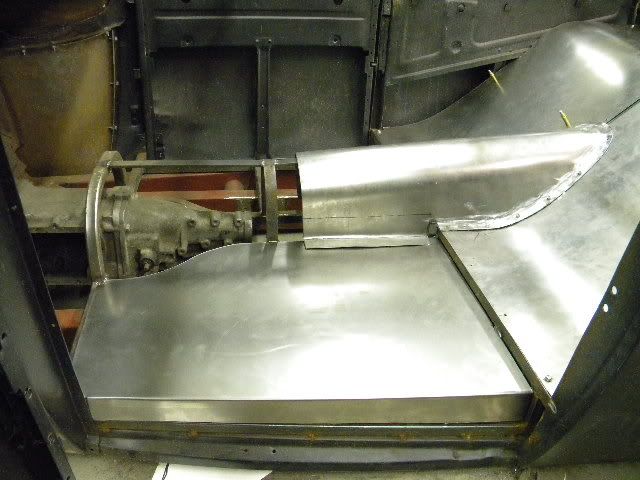

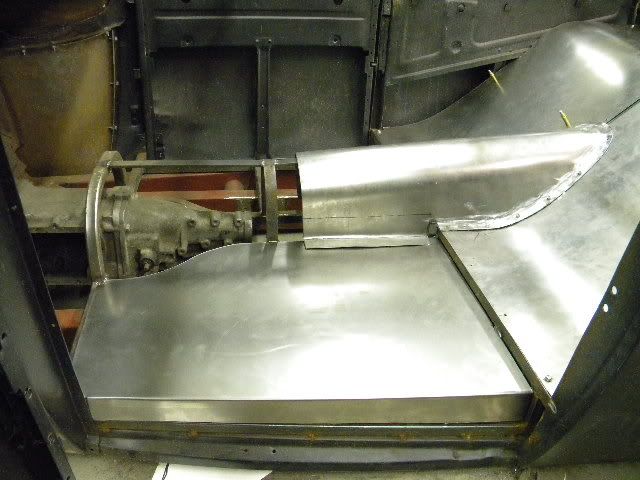

today i worked on the floor some more. first i made a cover plate to cover the access hole used to get to the air management system from inside the car if ever need to.

started on the center sections of the floor, and made a nice little sill plate area to dress it up a bit

started on the center sections of the floor, and made a nice little sill plate area to dress it up a bit