cornfield customs

Well-known member

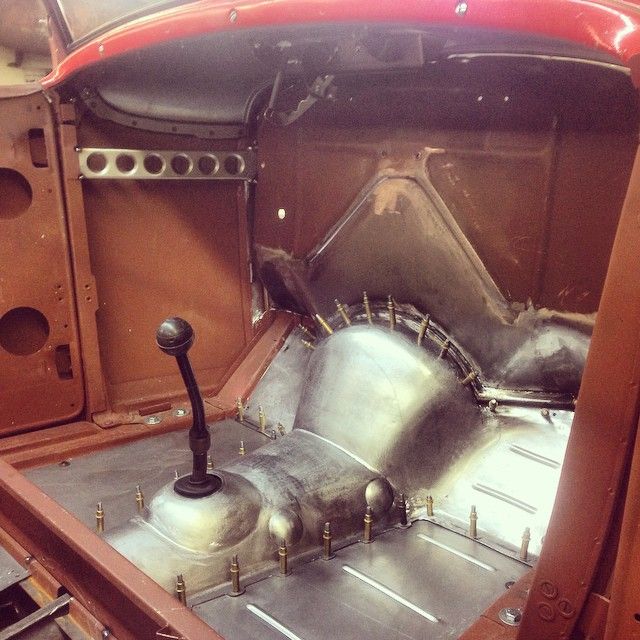

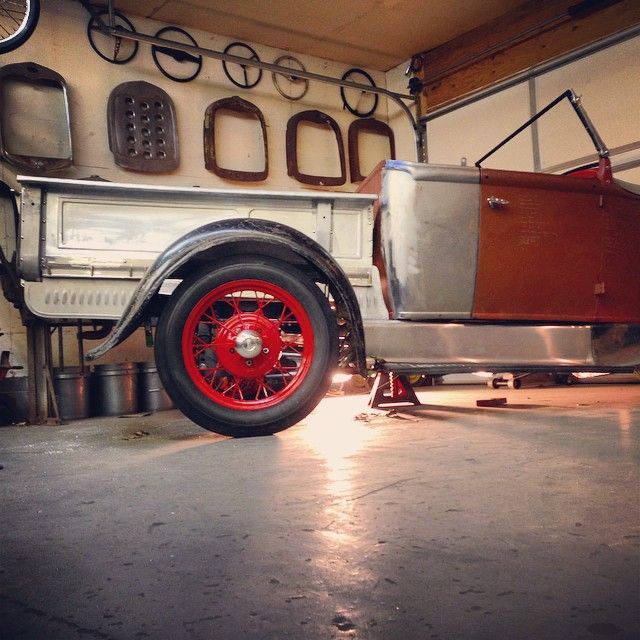

here is a dedicated build thread to the 30-31 roadster pick up i am building for a good friend of mine since high school. should be done for spring.

here is the frame in the jig on the table

start of boxing the rails, we are using our set of boxing plates, one of our flat x members

mocking up to get a good idea of the look.

the owner looking pretty pumped with 3 days worth of work in the evenings

here is the frame in the jig on the table

start of boxing the rails, we are using our set of boxing plates, one of our flat x members

mocking up to get a good idea of the look.

the owner looking pretty pumped with 3 days worth of work in the evenings