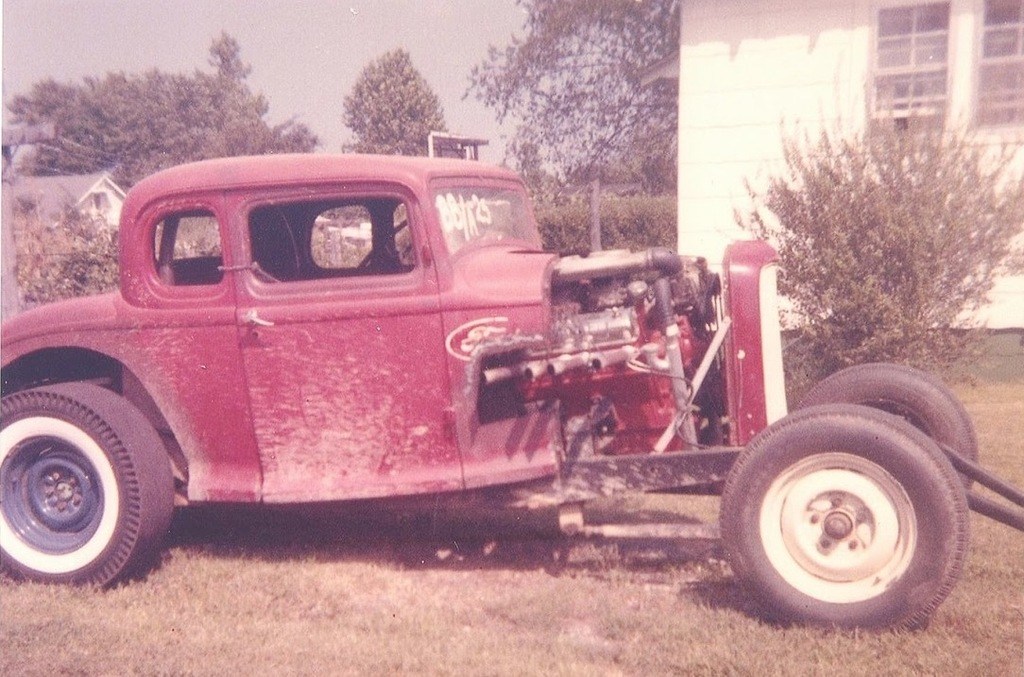

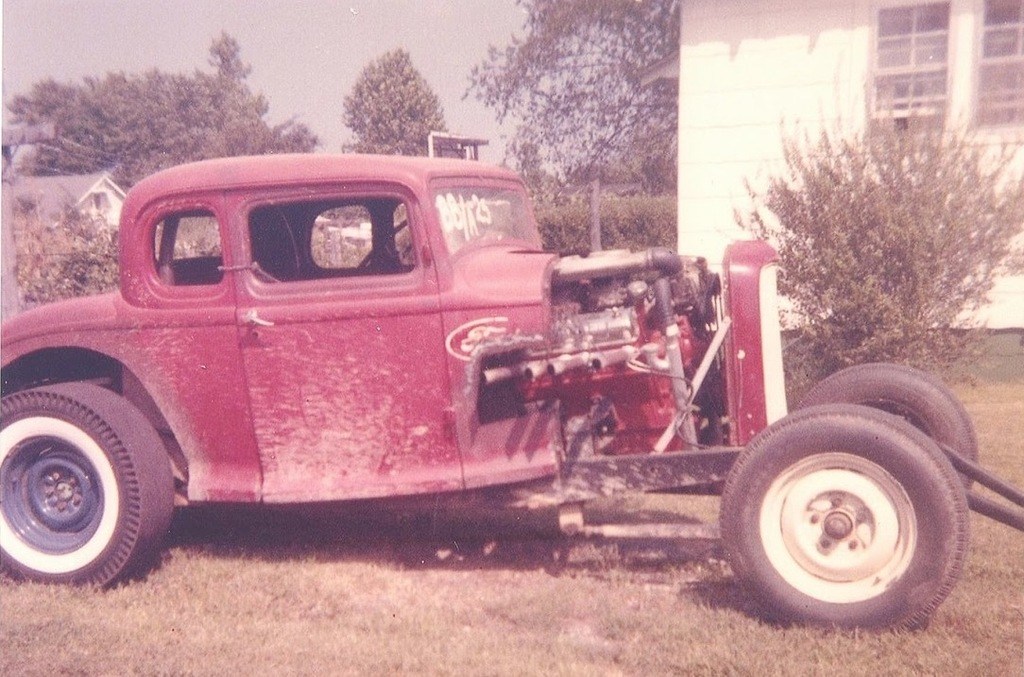

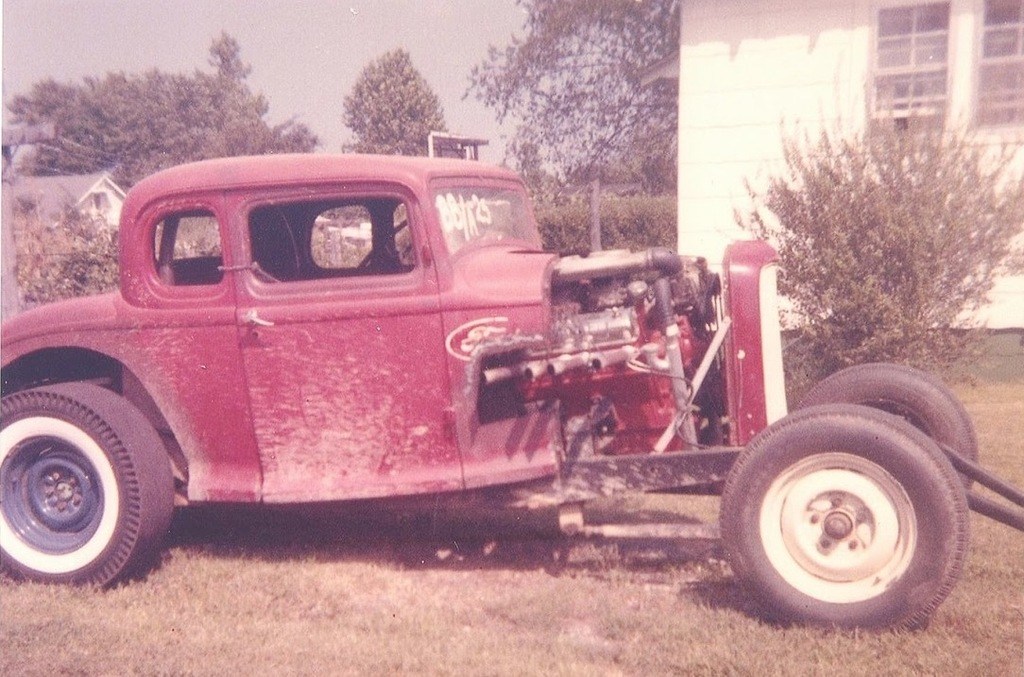

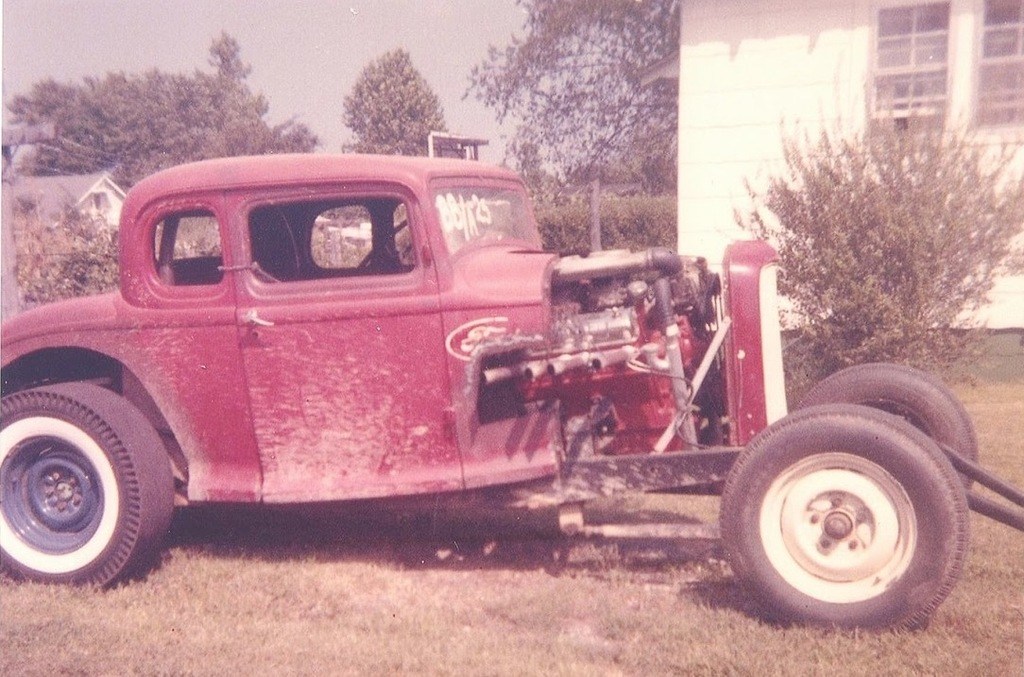

Old Iron

Well-known member

Start wiping

Start wiping