billy

Motor mouth ratchet jaw!

snapped off both motormount bolts flush on my engine block.

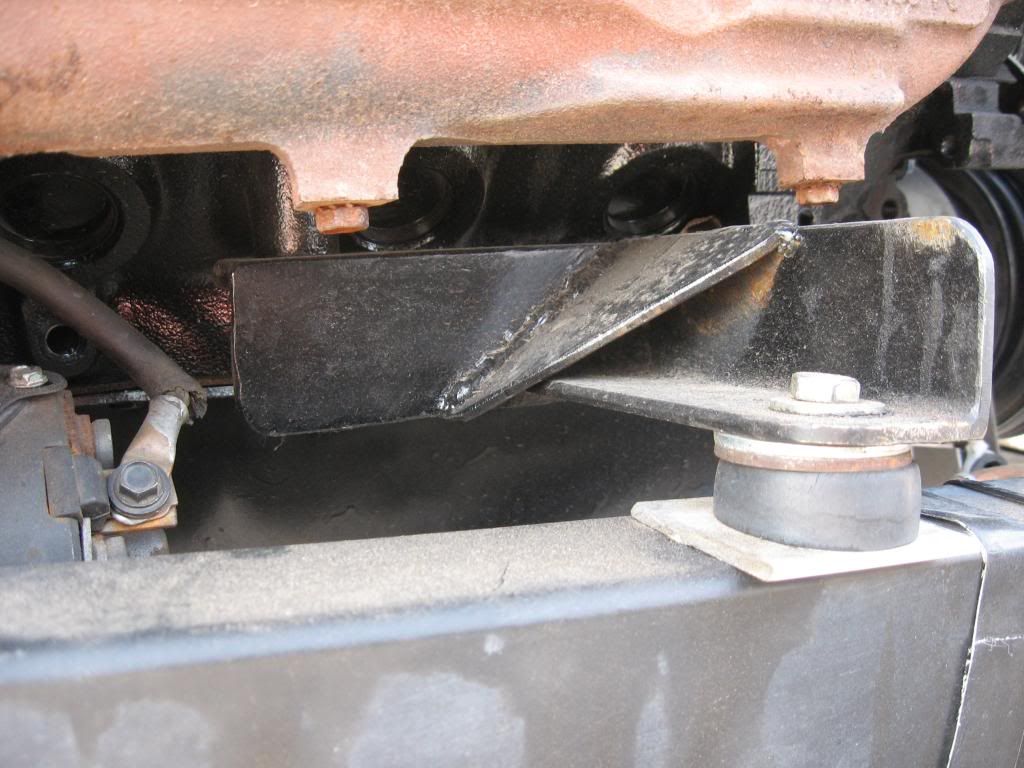

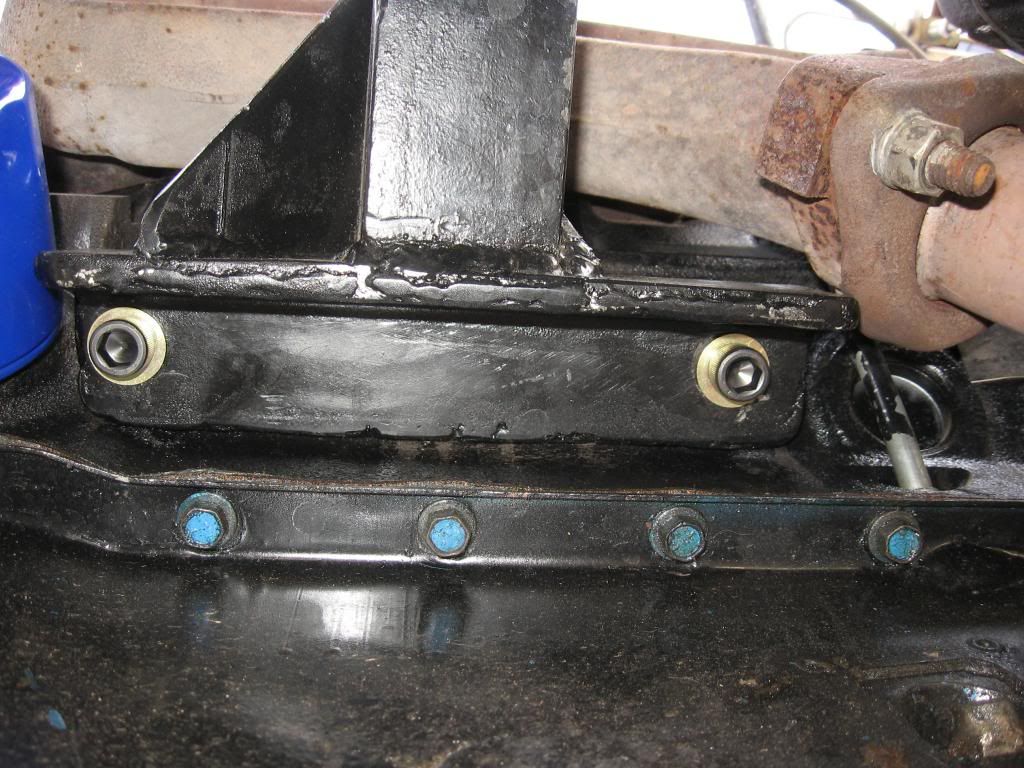

currently designing/modifying mounts to be able to handle the downward stress and take the load off those bolts.

this will be the 4th try.

does anybody have a photo or two showing how they did it?

as always thanks!

currently designing/modifying mounts to be able to handle the downward stress and take the load off those bolts.

this will be the 4th try.

does anybody have a photo or two showing how they did it?

as always thanks!