mikec4193

Well-known member

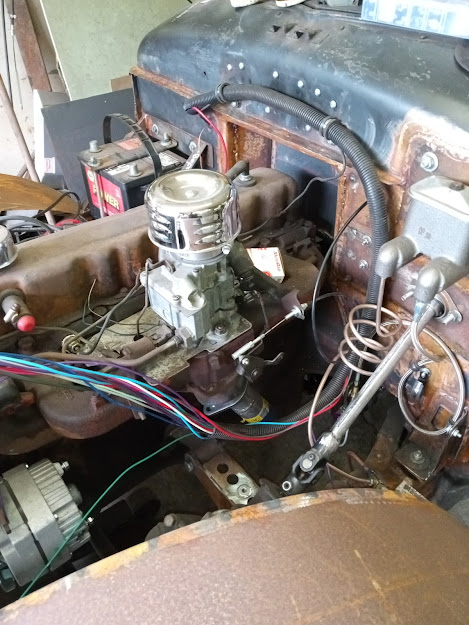

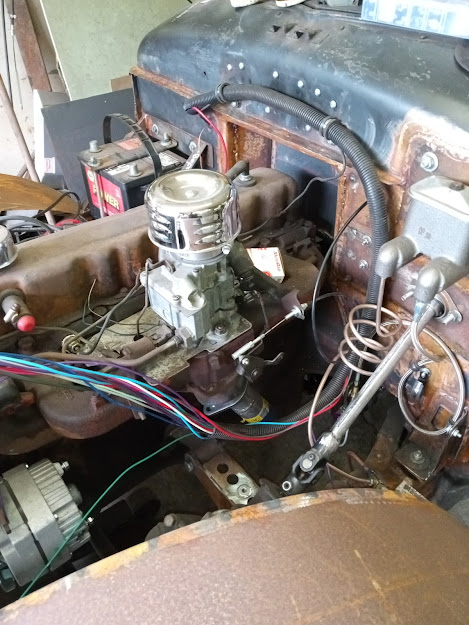

So I am to the point in my cobbing on this ole 1939 Plymouth

That I am adding fluids to make it stop and move...a nervous nelly for sure...

If I fill the reservoirs and open the bleeder screws on all the wheel cylinders and the clutch cylinder in theory the car should bleed itself, correct?...the wheel cylinders are lower than the reservoirs as is the hydraulic clutch cylinder.

Any insight would be awesome...

Can't wait to hear it run...

MikeC

That I am adding fluids to make it stop and move...a nervous nelly for sure...

If I fill the reservoirs and open the bleeder screws on all the wheel cylinders and the clutch cylinder in theory the car should bleed itself, correct?...the wheel cylinders are lower than the reservoirs as is the hydraulic clutch cylinder.

Any insight would be awesome...

Can't wait to hear it run...

MikeC