You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

weld on batwings on a 60 ford front axle?

- Thread starter 4drcaddy

- Start date

Help Support Rat Rods Rule:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

klink

Well-known member

Welding mild steel to forged steel has to be done properly. The problem is carbon. The forging (assuming its forged steel not a forged casting) will have a higher carbon content which will cause the weld to crack.

When welding dissimilar metals you will need to pre-heat and cool slowly. You may even want to provide heat after welding. 7018 will normally work.

There are several solutions, but the best one might be to find a professional welding shop to do the work.

Check out the builds section. There are LOTS of solutions for mounting the axle with bat wings without welding them on.

When welding dissimilar metals you will need to pre-heat and cool slowly. You may even want to provide heat after welding. 7018 will normally work.

There are several solutions, but the best one might be to find a professional welding shop to do the work.

Check out the builds section. There are LOTS of solutions for mounting the axle with bat wings without welding them on.

Last edited:

zzrodder

It ain't grey hair, it's chrome!

I personally think the bolt on batwings don't look so great - another solution that I have used a couple times is to cut off the old leaf mounts and drill through the axle to mount a conventional batwing with a single perch bolt early Ford style. Before drilling the axle, weld small filler plates front and back so the drill doesn't break through the center of the I beam. A much tidier look with not so much welding.

Attachments

bob w

Still crazy after all these years!

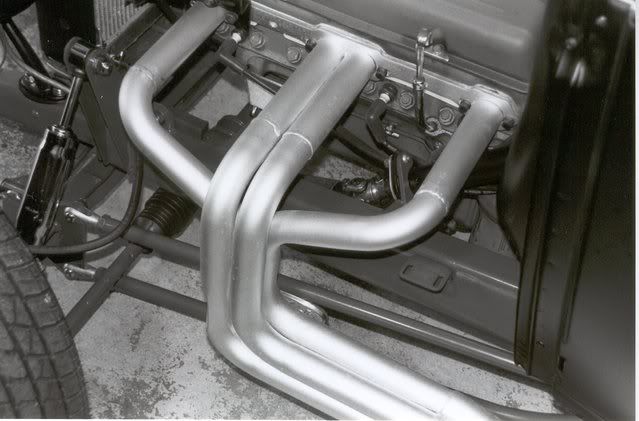

I welded bat wings on this Econoline axle successfully. Sorry I don't have a better pic.

bob w

Still crazy after all these years!

I did on this Chevy van axle what zzrodder shows above. Utilizing '35 Ford split wishbones instead of hair pins.

Bonehead

Skull Master

Most of these axles are drop forged, but I have heard of some cast steel axles. I would not weld on a cast axle, but drop forged takes a weld really well. There are a few ways to tell what you have. A grinder will throw a different color and size of spark from cast than steel. Rather than try to descibe it, just get a piece of cast and grind on it and compare it to steel. Cast also drills up in little pills, not the typical corkscrew look from drilling mild steel. Welding on an axle should not be the first weld you ever make.

i am a welder fabricator by trade but i am not gonna lie i never welded forged to mild and i am not afraid to ask. i am being told preheat. 7018, then let cool slowly........ but its not mild to mild .......... its forged to mild?

iam confusing myself...... am i overthinking this?

iam confusing myself...... am i overthinking this?