kelseydum

Well-known member

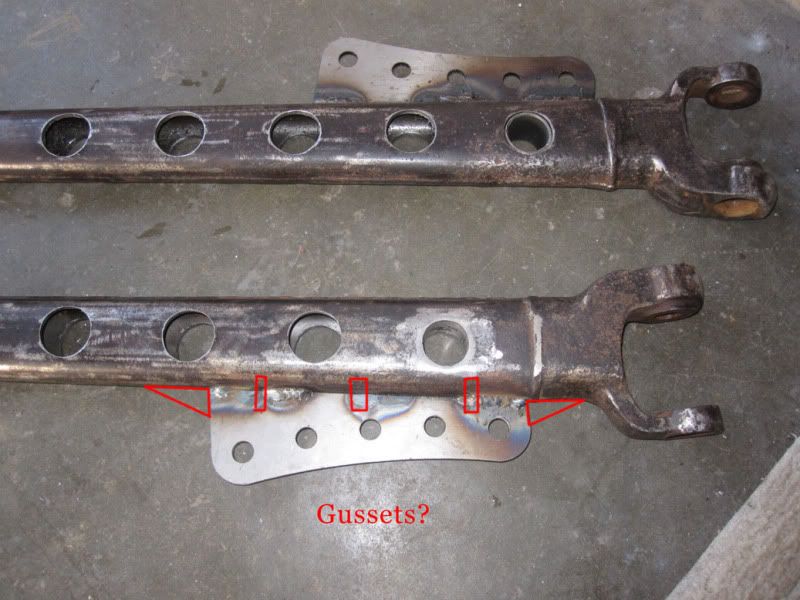

I finally about got my wishbone done. I had a question about the tubing I need for the lightening holes. Is there a specific size (wall thickness) I need for these or can I just get some tubing with like a 1/16" wall? I had enough around the shop to do the first hole in each of them but wanted to ask this before I do the others. I drilled a 1 1/4" hole with the tubing in makes it about 1 1/8". Do I have enough room to drill one more... is one more needed... do they look okay?

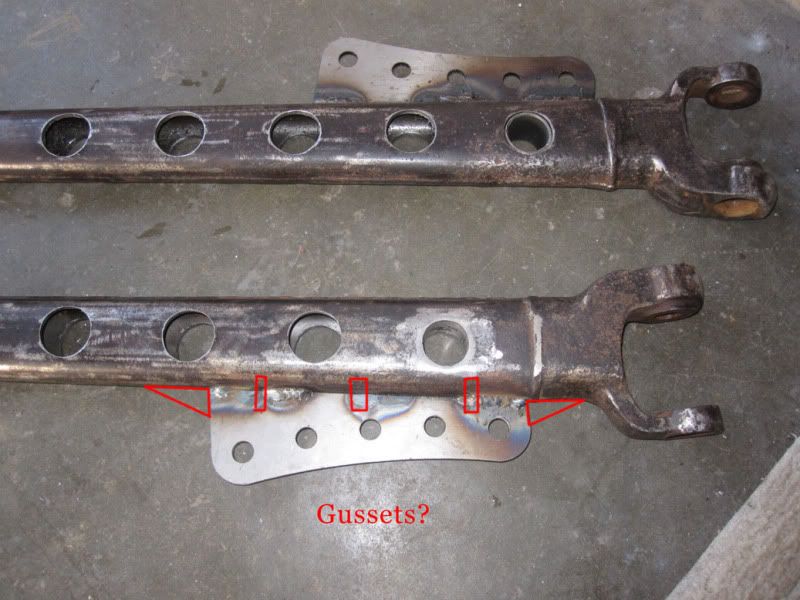

Also the brackets for the spring pivot I got from speedway. Are these going to need some gusseting? The plate is about 1/4" thick.

Here are some pics...

Also the brackets for the spring pivot I got from speedway. Are these going to need some gusseting? The plate is about 1/4" thick.

Here are some pics...