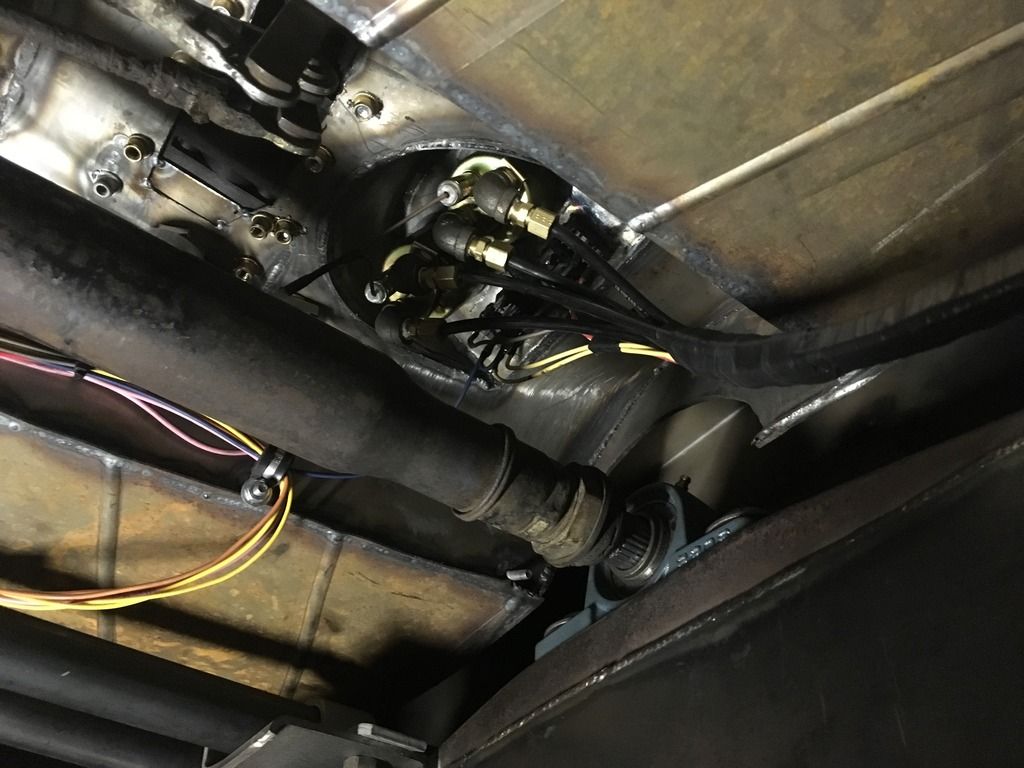

I like the heat shield.

What are you going to use for a quick release on your steering wheel? I ended up machining a 3 bolt to hex/with lock groove adapter for mine since I didn't want to weld the shaft adapter that came with it onto my aftermarket column.

What are you going to use for a quick release on your steering wheel? I ended up machining a 3 bolt to hex/with lock groove adapter for mine since I didn't want to weld the shaft adapter that came with it onto my aftermarket column.