cornfield customs

Well-known member

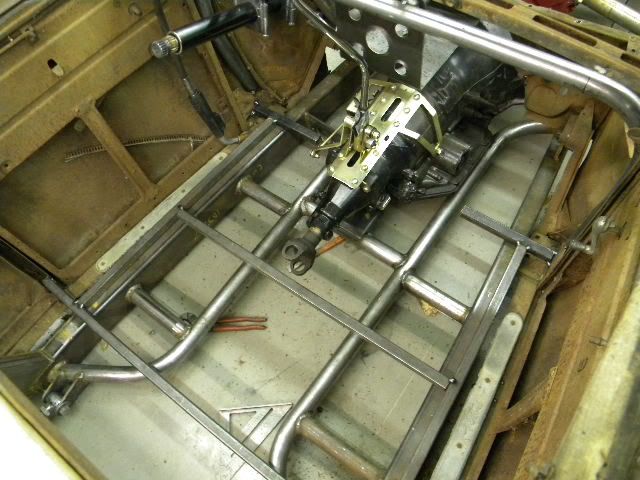

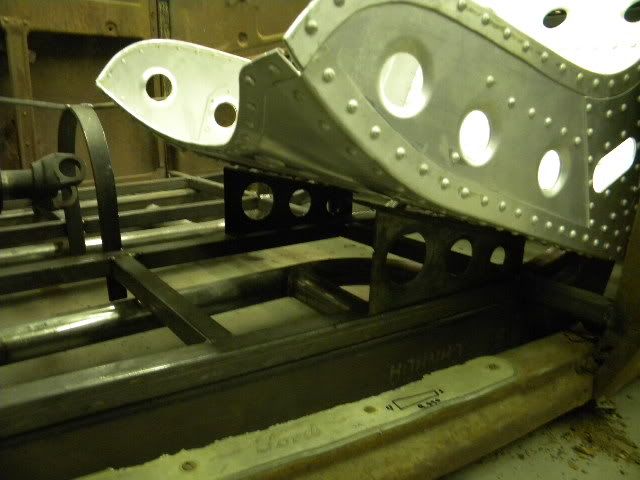

The pitman arm took about an hour to layout and make. So it wasn't to bad.

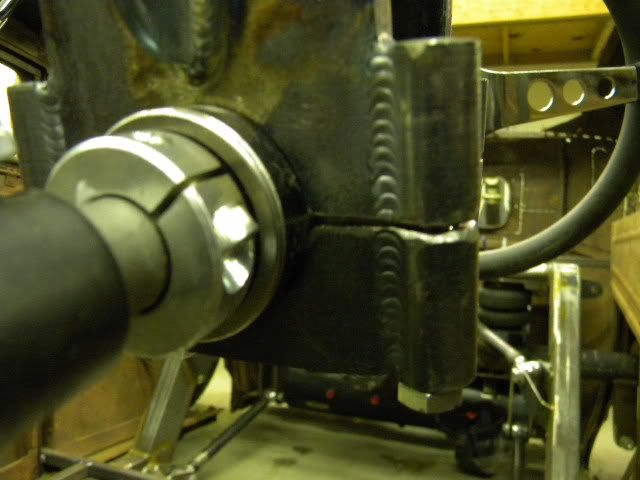

The steering box is a reversed corvair box.

And my shoes are leather they work well as long as I don't drop frames on them lol

The steering box is a reversed corvair box.

And my shoes are leather they work well as long as I don't drop frames on them lol