Dr Crankenstein

Rocket Surgeon

Could be!Couldn't get that last case of shine in without buckling the lid [ddd

Don't get me started.Mother-in-law maybe? [ddd

.

Could be!Couldn't get that last case of shine in without buckling the lid [ddd

Don't get me started.Mother-in-law maybe? [ddd

What is the style y'all are going for with this one Doc? You know these Chevy coupes make awesome taildraggers right?

Better a touch not enough than too much, you can always toss a shim in for alignment if required. [cl

Thanks guys.

No taildragger, no chop, no airbags, no trashy billet trinkets. No big, stupid, ugly wheels with rubber band tires. No door poppers, no power windows, no bullship bling. No fancy, fruitcake, pearl, flip flop glow in the dark paint.

We're looking for a simple, clean, classic Hot Rod to drive on our rough streets and roads. It'll be plenty fast and fun. It'll probably never see a car show, that's not the purpose, so anything more is a waste of time and money!

.

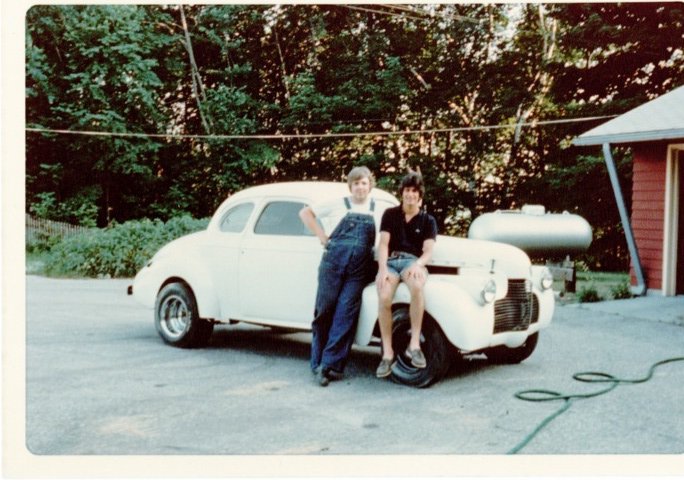

Do you mean like this one.

My 1940 Chevy Coupe. Back when Torchie was a younger man.[ddd

Old Torchie.

No taildragger, no chop, no airbags, no trashy billet trinkets. No big, stupid, ugly wheels with rubber band tires. No door poppers, no power windows, no bullship bling. No fancy, fruitcake, pearl, flip flop glow in the dark paint