You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

MAIDEN Build. 46' IH Rat Truck

- Thread starter IRON MAIDEN

- Start date

Help Support Rat Rods Rule:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

IRON MAIDEN

Well-known member

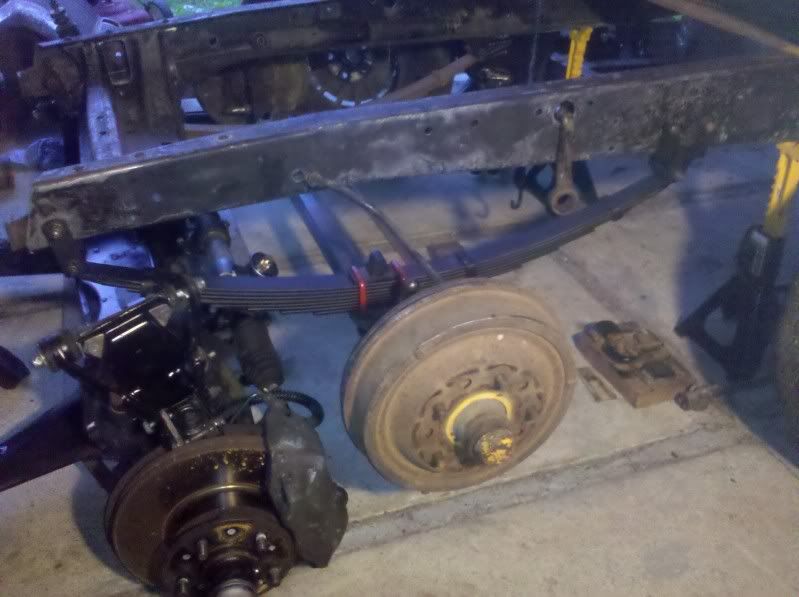

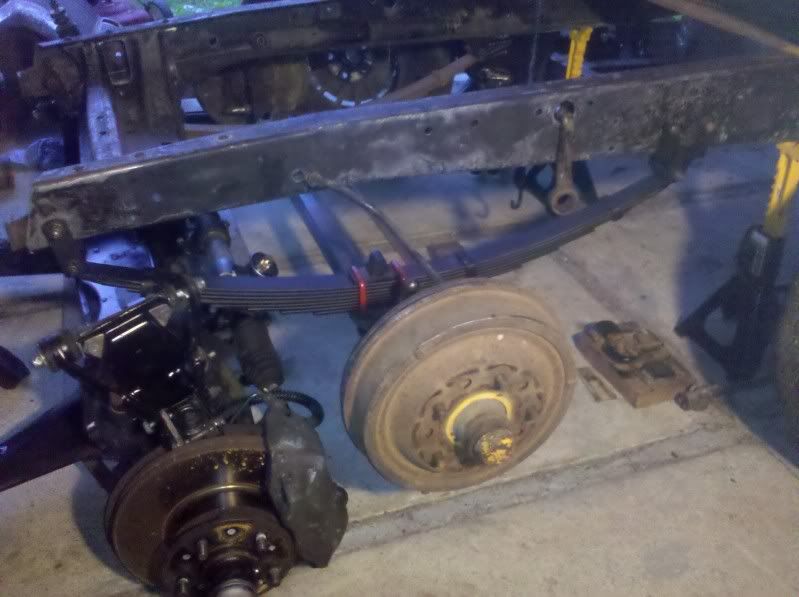

I think I have a winner. Im at at estimated axle centerline position, but it's close. The back mounts will bolt right to the frame. Front mounts should be easy. I was hoping the rack pinion would be closer to the frame but it's not too bad. No room for the sway bar as it sits. The front crossmember if in the way. I need to get back over there and get the rag joint and swaybar. I can always box the nose of the frame and cut half the front crossmember out. Half of it is the radiator support and the other half, that dips down below the frame and is in the way, is the motor mount. I won't need the motor mount so if I have to nip it a bit....

IRON MAIDEN

Well-known member

IRON MAIDEN

Well-known member

IRON MAIDEN

Well-known member

IRON MAIDEN

Well-known member

$44.99

Bobby Unser (Indy Car), "Autographed" (JSA) Business Card (Scarce /Vintage) - Autographed NASCAR Cards

Sports Memorabilia

$24.99

1976 Hot Wheels 31' Doozie Convertible Orange Brown Vintage Toy Car Hong Kong

Hockey Card World Inc.

$205.19

$239.99

Solary Magnetic Induction Heater Tool - 1000W 110V Handheld Rusty Bolt Removal Tool with 8 Coils

solary

$26.99

Ekouaer Women's Skorts Tight Biker Short Stretchy Breathable Sports Cute Skirts ArmyGreen

Ekouaer loungewear

$64.99

A.J. FOYT HAND SIGNED VINTAGE 5x7 COLOR PHOTO+COA LEGENDARY RACE CAR DRIVER - Autographed NASCAR Photos

Sports Memorabilia

$34.99

1980's The Sunshine Van Bedford CF Red Summer Vintage Toy Car Hong Kong

Hockey Card World Inc.

$229.99

$259.99

Solary Magnetic Induction Heater - 1000W 110V Handheld Bolt Removal Tool with 12 Coils

solary

$11.75

Cable Car Turntable Powell & Mason -San Francisco California - Vintage Linen Postcard

grinvideoproductions

$159.99

$179.99

Solary Magnetic Induction Heater Kit - 1000W 110V Induction Heat Bolt Removal Tool

solary

$29.99

1979 Matchbox Superfast Yellow Citroen CX Vintage Toy Car Made in England

Hockey Card World Inc.

IRON MAIDEN

Well-known member

damucthat?

Active member

Wow Good look'n truck....Nice find!!

IRON MAIDEN

Well-known member

So that IFS subframe is complete with 4 total mounting points?

You don't need to weld a chopped frame to a chopped frame and fabricate upper a arm mounts?

-Chaz

Do some searches on the Jag IFS and the IRS. You can cut off all the mounts to clean up the crossmember and weld it in solid, or rubber(soft) mount it with the Jag mounts. The back looks like it will pretty much bolt through the bottom of the frame. The fronts will need some tabs fabbed up to hold the front mounts. ; )

IRON MAIDEN

Well-known member

/glee

??? Huh? [S

IRON MAIDEN

Well-known member

Me too.

IRON MAIDEN

Well-known member

Man. I forgot how curvaceous the front fenders are on this beast. Love em'.

My grille looks pretty good after all the work I did on it. It's still bowed in a bit in the middle, but should be easy to straighten it up. Plus all the seams were dead on.

I just didn't feel good about the measurements I had for my axle centerline and didn't want to risk having my wheels not centered in the fenders. So I mounted the grille and fenders to be sure I am mounting the Jag in the right spot. No real progress mounting this thing, life is getting in the way right now. But, it sure looks cool with the nose on! [dr

Anyone care to estimate how much more drop I'll get with a 327/700R4 combo?

My grille looks pretty good after all the work I did on it. It's still bowed in a bit in the middle, but should be easy to straighten it up. Plus all the seams were dead on.

I just didn't feel good about the measurements I had for my axle centerline and didn't want to risk having my wheels not centered in the fenders. So I mounted the grille and fenders to be sure I am mounting the Jag in the right spot. No real progress mounting this thing, life is getting in the way right now. But, it sure looks cool with the nose on! [dr

Anyone care to estimate how much more drop I'll get with a 327/700R4 combo?

IRON MAIDEN

Well-known member

Here's where I'm at. I had some 1/4" steel plate, well the bumper that used to be mounted to the truck did, so I cut all the pieces out of that. Actually I had my buddy cut it up. Some stout 3/8" steel as well. At least I'm recycling the bumper back into the truck ; )

IRON MAIDEN

Well-known member

Still need to grind/shape it some more to get it how I like, but this is the basic idea.

IRON MAIDEN

Well-known member

The rear rubber mounts will bolt up to the center of the frame rails. I still need to decide on how I'm gonna come off the bottom of the plate to mount up to the front Jag Donut.

I'm tossing up the idea of just some tabs out of the 3/8" plate with a gusset between the two in the front/boxing the front of the tabs. It would simply be welded and fixed in place.

Or something like this that could be bolted to the bottom of the plate. Then I'd have the ability to shim the front and rear mounts to adjust the caster of the crossmember.

I'm tossing up the idea of just some tabs out of the 3/8" plate with a gusset between the two in the front/boxing the front of the tabs. It would simply be welded and fixed in place.

Or something like this that could be bolted to the bottom of the plate. Then I'd have the ability to shim the front and rear mounts to adjust the caster of the crossmember.

IRON MAIDEN

Well-known member

I cut some quicky 1/4" tabs to tack up the front mounts. It levels the crossmember as the truck sits right now and will be fine until I get closer to redoing them. Problem I'm seeing now is the clearance for the swaybar. Only have 1/4" between the bottom of the bushing retainer and the crossmember arms. Not sure how much the crossmember will move but I/m guessing it will hit here. Think I'm gonna seperate the big plate and raise the swaybar portion to level it with the bottom of the frame. This will give me another 1/4" of clearance.

I wouldn't imagine that the bushings that the crossmember mounts with would have enough deflection in them for the sway bar to hit anyway.

They would only be there to isolate vibration I'd think. If they moved too much you'd get caster change under brakes and lose all small bump sensitivity in the shocks...

They would only be there to isolate vibration I'd think. If they moved too much you'd get caster change under brakes and lose all small bump sensitivity in the shocks...