You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Smallfoot's AA

- Thread starter smallfoot

- Start date

Help Support Rat Rods Rule:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Torchie

Well-known member

Floor is looking great Smallfoot.

Another huge leap forward.[cl

What gauge sheet metal are you using?

Torchie.

Another huge leap forward.[cl

What gauge sheet metal are you using?

Torchie.

smallfoot

He's rockin' the "Nuttin Special"!

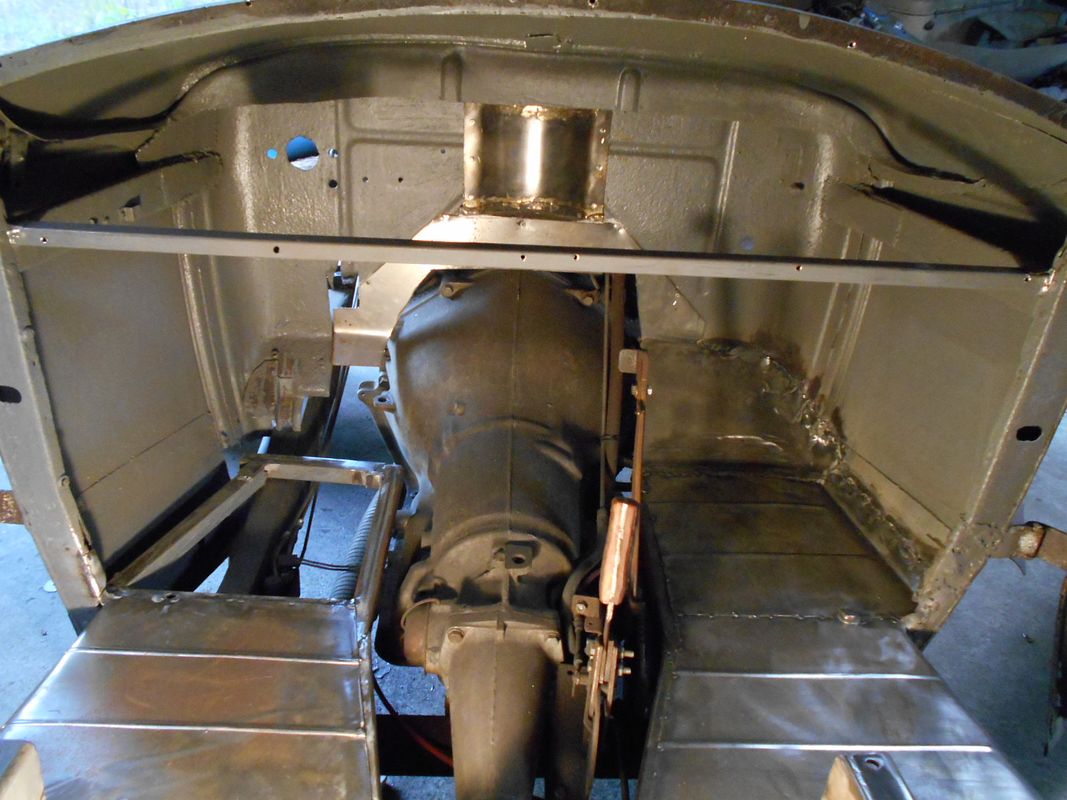

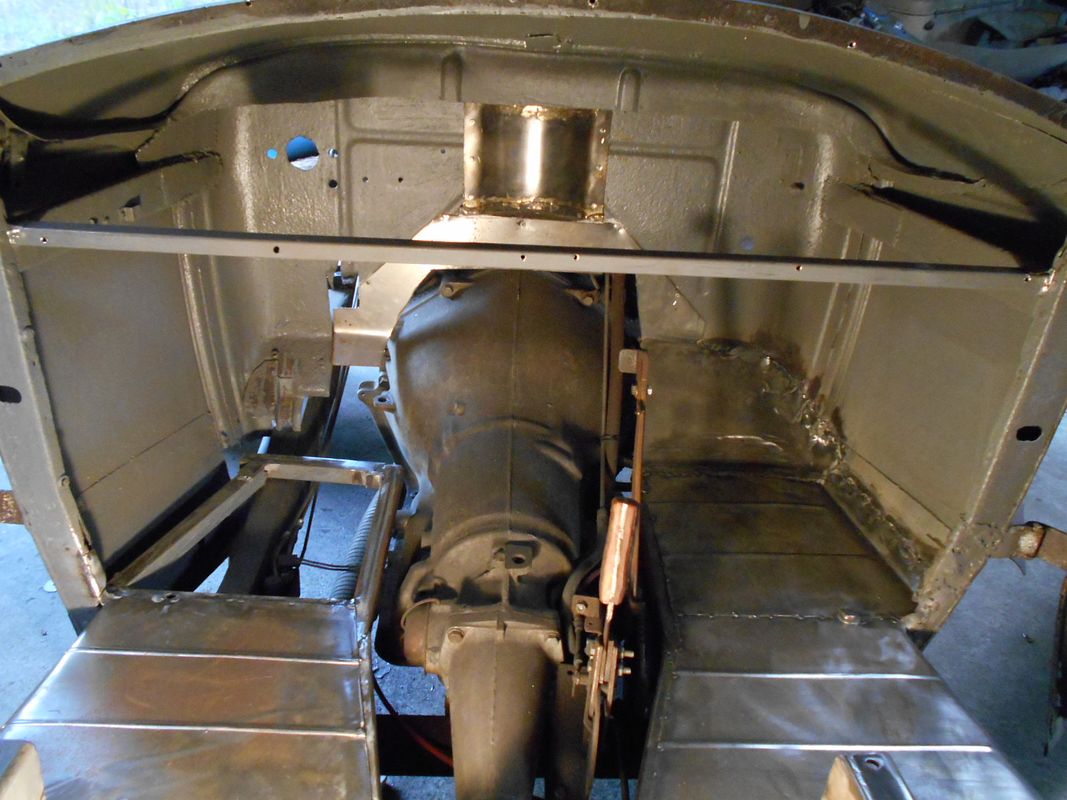

Using up the rest of the 18 ga. stuff I have on hand. It's a little flimsy across wide areas of floor frame but the widest stuff I have is 10" apart and I'm placing some beads across the high travel areas. The beads really firm things up...Floor is looking great Smallfoot.

Another huge leap forward.[cl

What gauge sheet metal are you using?

Torchie.

Closing in on the tranny tunnel and thinking along the way of what I'll do when I get there is slowing me down. It's pretty much play as I go at this point...lol!

Todd

He's just one of them Rusty-Chainers!

You have a cool build going. Thanks for sharing.

smallfoot

He's rockin' the "Nuttin Special"!

Thanks for the good words Todd!

Old Iron

Well-known member

Your ride really looks good.

Nice work on the dash, firewall and floors

Nice work on the dash, firewall and floors

smallfoot

He's rockin' the "Nuttin Special"!

Thanks Old Iron! It's coming along slowly...

smallfoot

He's rockin' the "Nuttin Special"!

Got the passenger side tacked in and got another drivers side panel in. I have the last floor panel cut, but ran out of daylight and need to fab an access panel into this one along with some beading. The access hole will give me an "easy in" for tranny linkage and prop valve. If I can figure a way, I'd like to make a door that removes completely with a twist of a ring. My old 42 Ford Jeep had ammo boxes with lids like that and they didn't rattle and were pretty tough too.

Torchie

Well-known member

Good looking progress smallfoot.

With your ingenuity and talent you will come up with something.

Torchie. [ [

[ [

[ [P

[P

With your ingenuity and talent you will come up with something.

Torchie. [

Old Iron

Well-known member

Might consider using Zues fasteners.

smallfoot

He's rockin' the "Nuttin Special"!

Hey Old Iron thanks for the idea. Those Dzus fasteners are nice and along the same idea of what I'm thinking of doing. Mine will be a center stud on the cover with a folding ring and capable of two point contact on the floor opening. Still playing with my ideas and will post pix of what I come up with.

smallfoot

He's rockin' the "Nuttin Special"!

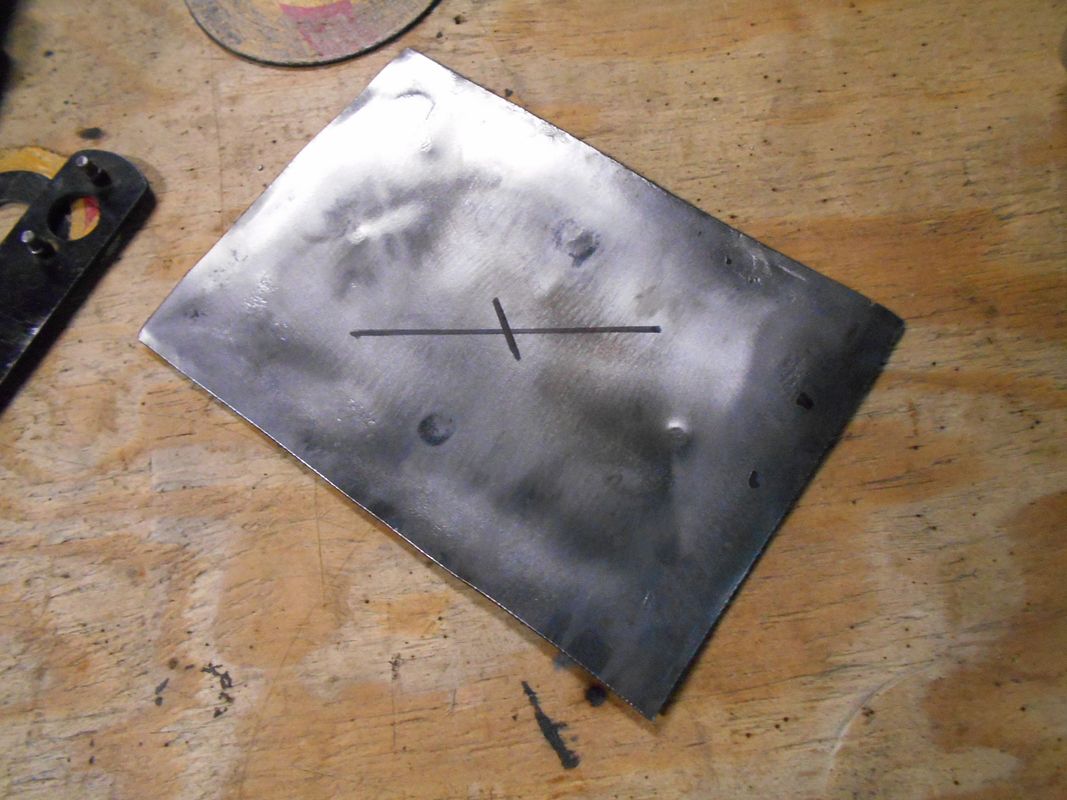

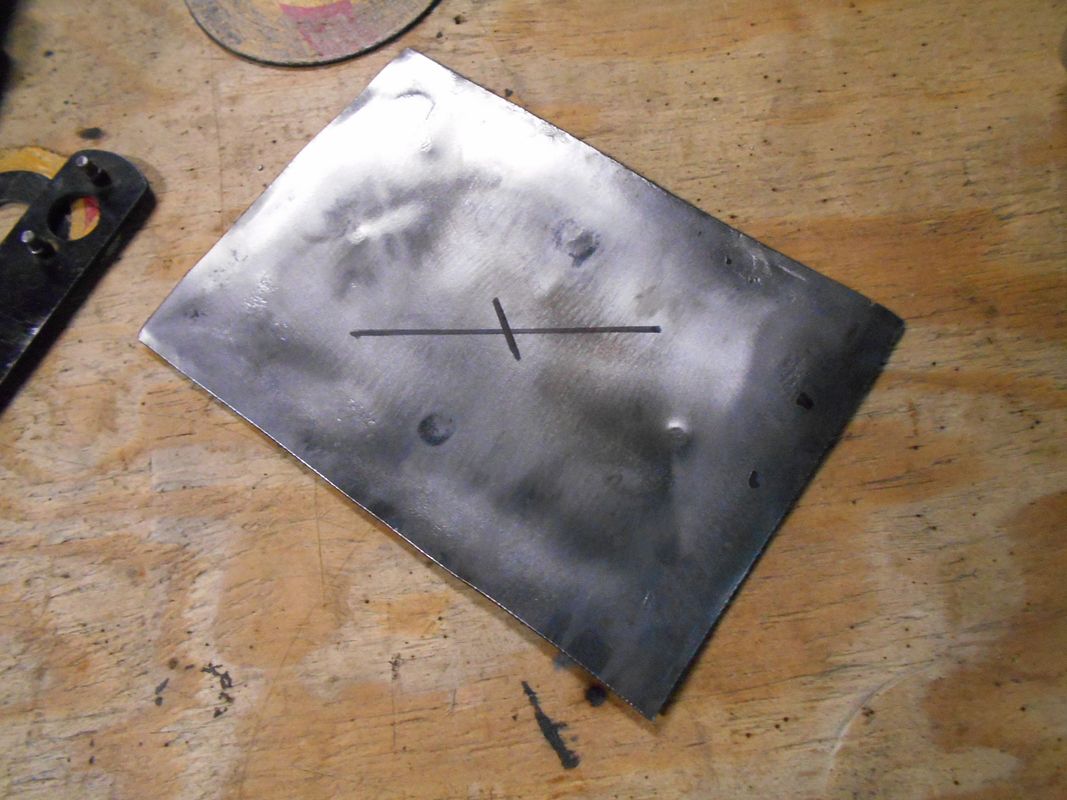

Here we go! Cut a couple of pieces of sheet, one a little smaller than the other. Brazed the two pieces together for strength and a positioning lip. Cut a centered hole thru both pieces and brazed a large washer underneath to give it a dish area to level the ring. Fashioned the stud with a 3/8" bolt. Flattened on 2 sides to match a slot cut into the holding arm. Then flattened 2 sides of the other end and lost the head. Drilled it for the ring. Still have to cut the opening in the floor panel and make adjustments for a tight fit. Thanks for stopping by...

Old Iron

Well-known member

That's a nice lookin piece

Yankee Transplant

He started out with nothing, he still has most of

well thats a cool looking hatch lid

smallfoot

He's rockin' the "Nuttin Special"!

Thanks guys! Hopefully tomorrow I can get the panel set up and see how it looks in the floor. Looks as if the thing will work.

Torchie

Well-known member

Way cool smallfoot.[cl

What did you use to make the machine turned pattern?

Your dash would look great like that.[ddd

Torchie.

What did you use to make the machine turned pattern?

Your dash would look great like that.[ddd

Torchie.

smallfoot

He's rockin' the "Nuttin Special"!

Torchie, That was done with a small cup wire brush in the drill press. I did it without a pattern by eye. It would look better if I put it in the mill vise and kept the pattern even. It was done mostly to cover up all the blems in the cover after having to beat the snot out of it. It got wavy after putting all the heat to it and I had to take it to the anvil to get it flat again. I thought about doing the dash, but don't think it would be noticeable after paint.

AZRodDave

Well-known member

Well done, sir!

Torchie

Well-known member

Torchie, That was done with a small cup wire brush in the drill press. I did it without a pattern by eye. It would look better if I put it in the mill vise and kept the pattern even. It was done mostly to cover up all the blems in the cover after having to beat the snot out of it. It got wavy after putting all the heat to it and I had to take it to the anvil to get it flat again. I thought about doing the dash, but don't think it would be noticeable after paint.

That's why you wouldn't paint it. Just shoot some clear over it.[ddd

Or you could just do your glove box doors and still paint the main dash area.

You just don't see a whole lot of this type of work much anymore. At least I don't.

Von Dutch used to while away his free time making machined turned panels for just about anything.

Just my spare 2 cents for today.

Carry on.....

Torchie.

smallfoot

He's rockin' the "Nuttin Special"!

I understand your thoughts Torchie! I really like the looks of machine turned or "jeweled" pieces too. It's a process I used in my more expensive custom knives. I've got my mind leaning toward paint for the dash already though and haven't come away from it yet...I may change my mind when I see it in paint(thinking same gray for doors and panels and flat black for main dash) and I'll keep my mind open. If the material for the dash or dash doors was anything but steel, like brass or copper, I'd just machine it and leave it. Might be just a little too fancy for a barn rat...lol!