pistolpete

Well-known member

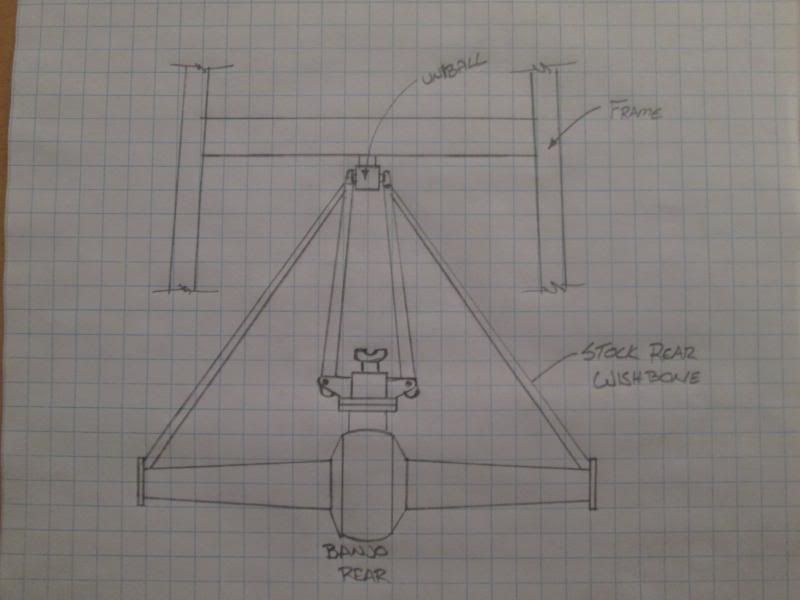

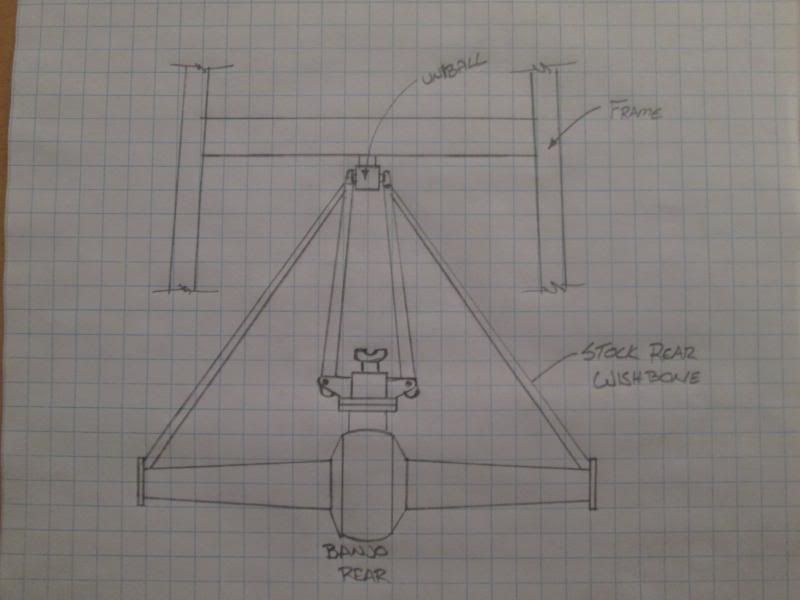

My build is slow moving, partly due to me wanting to keep it a roller. But I have been piecing things together, I am using a '40 banjo rear open drive from a flathead/T5 combo. I want to do a triangulated rear similar to the stock set up with wishbones or some sort of ladder bars, but don't want typical tube ladder bars. If I go with making a ladder bar I will make some sort of tapered tube. I did a quick mock up of what I am thinking with '40 front wishbones, but this option will require another set of front wishbones, a cost I'd rather not endure. The wishbones would then mount to a uni-ball joint (like 4x4 link ends) mounted on a new cross member with the ball as close to directly under trans yoke as possible. Hopefully the sketch helps explain better then my words.

Do you think a 3/4" bolt through the UniBall would be sufficient in this application? http://www.4wd.com/Fabrication-Tool...spx?t_c=86&t_s=528&t_pt=101460&t_pn=R/ERE3795

More or less looking for some feedback don't have anyone to bounce ideas off of, and the wife looks at me crooked when I ask her opinion.

Do you think a 3/4" bolt through the UniBall would be sufficient in this application? http://www.4wd.com/Fabrication-Tool...spx?t_c=86&t_s=528&t_pt=101460&t_pn=R/ERE3795

More or less looking for some feedback don't have anyone to bounce ideas off of, and the wife looks at me crooked when I ask her opinion.