endicott_jb

Well-known member

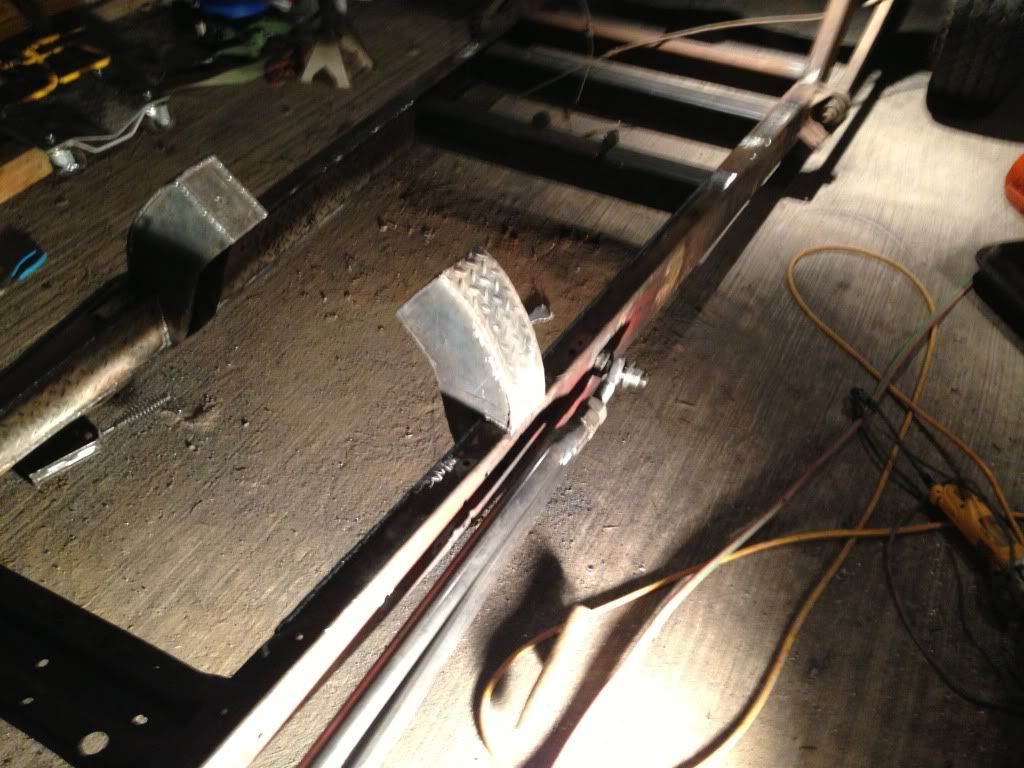

Okay, so I think I understand now. When you brake, the axle wants to twist due to the momentum of the car and under hard braking, it would twist even further and the only place that's keeping solid pressure is the radius arms and the spring perch. So, I broke out the torch, cut the old brackets off, made new ones and moved them out about 3 more inches so that they are in line with my spring brackets. Now, obviously this is only a mock up but my idea is to make a few more brackets to mount an upper rod on each side and weld the upper to the lower rod. Anyhow, here's a picture to show what I have in mind. Mind you, the upper rod is just sitting across and it won't be where it's at. Just for demonstration purposes only.