Chaz

New member

Hey you look like you are doing really good with your build. Thanks you have given me ideas to work into my project.

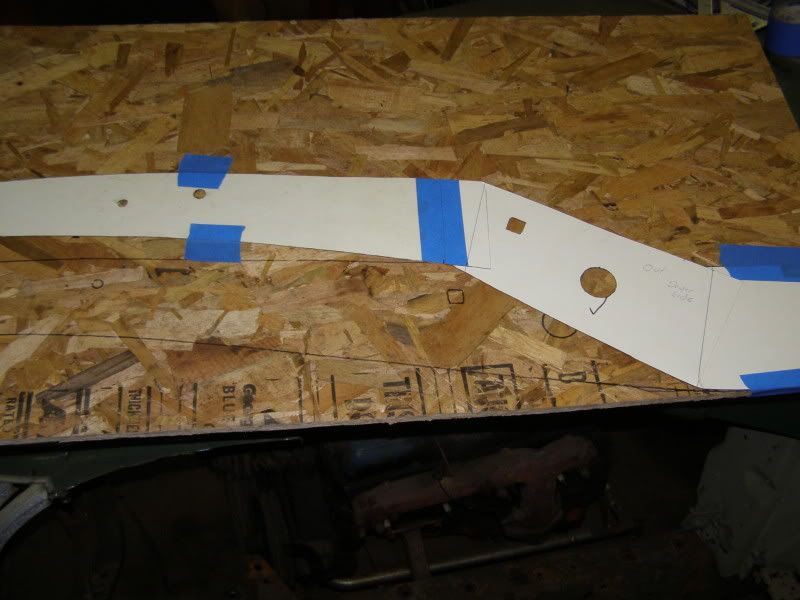

well heres the start of the frame. this will be the last time i work with a frame this way.

i could have built a tube frame so much quicker that fitting this oem frame, live and learn.

Enter your email address to join: