I'm leaving the horns alone for now. There's bigger fish to fry.

Speaking of frying: Now that I can build boost in high gear, I'm seeing a new realm of engine operation. When I'm running around 200° and the boost comes up to around 3-4 pounds, the pinging starts. I expected this. So, I finally hooked up the boost retarder that I made...

This module with 5 pins ******* the timing when the fifth pin is grounded.

I found a fitting in my bins, and threaded the inside of the male end to fit a pressure switch.

I put a fitting on the other end:

Then made a bracket:

Now I finally took the fuel pump off:

The wire comes out of the distributor, down to the switch, and from the other side of the switch, it grounds to the block. My manifold pressure line goes to the switch, then to the vacuum advance canister.

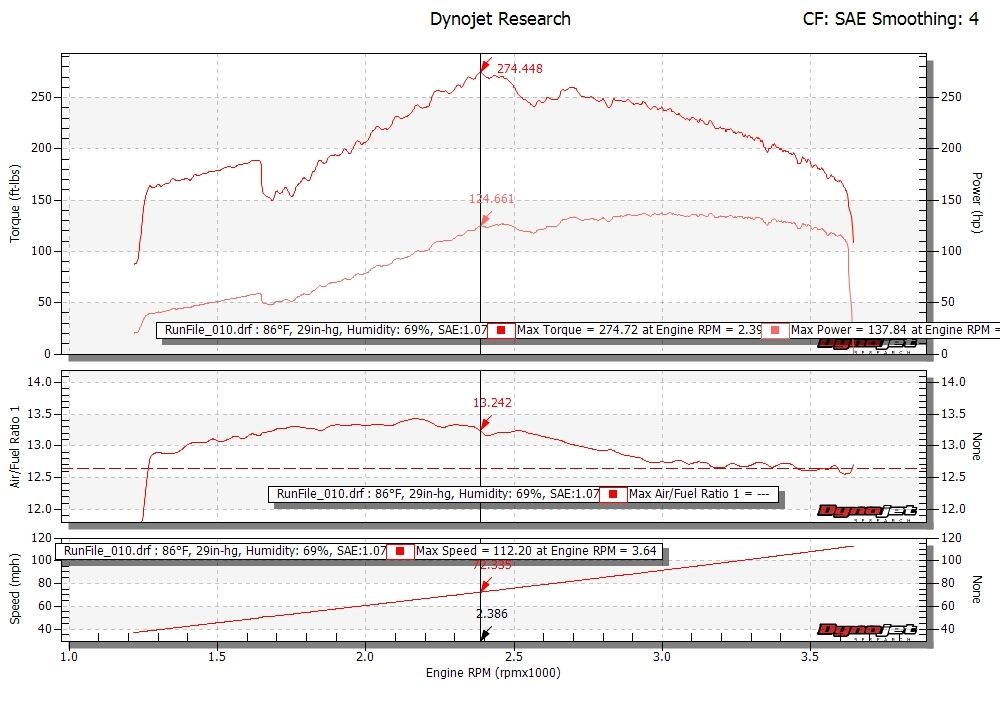

Under vacuum, the can adds 9°. When I hit 2 pounds of boost, the module pulls about 10° out. The odd thing is, at idle speed around 6-700 RPM, the module pulls about 16°, at 2000 RPM it pulls about 10°, and at 3000 RPM, it pulls about 7°.

In high gear, at wide open throttle, I hit 2 pounds of boost at about 1500 RPM. The timing *******, and I feel it lose a little power, but then it's putting a lot of combustion into the exhaust, and then the turbo really starts to spool up. It's sorta strange to get used to. In second and third gear, I can't feel it. I can hear it in the exhaust, and the exhaust temperature jumps up a few hundred degrees.

Having an oil-cooled turbo, means I have turbo-heated oil.

So; more throttle → more boost → later timing → hotter exhaust → even more boost → hotter oil → hotter engine → more prone to knock, etcetera.