deerchooper

Well-known member

- Joined

- Apr 3, 2010

- Messages

- 744

looking good motorhead.

i know all about those days you just had,lol.

i know all about those days you just had,lol.

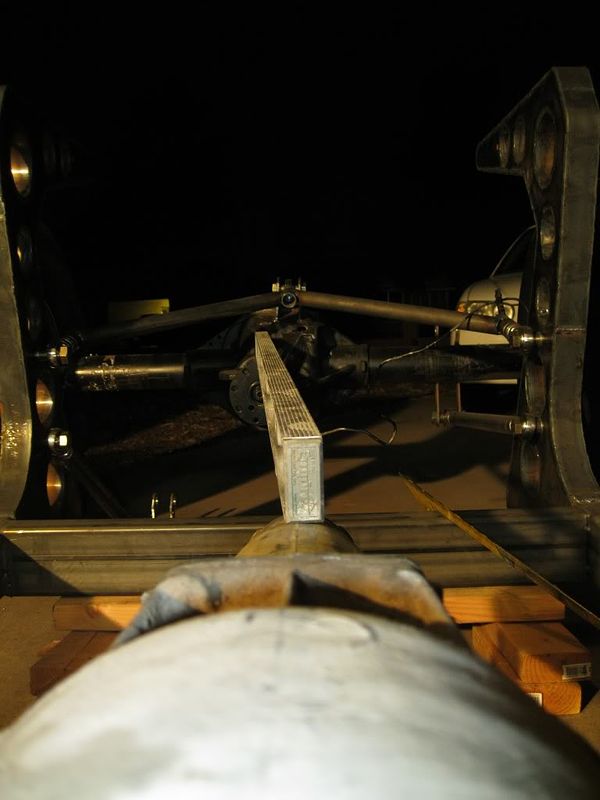

LOOKIN' GOOD !! The Caddy looks right at home there. When I mounted the Caddy in my frame, I used some leftover poly bushings for Chev pickup leaf springs for mounts, made ears to bolt to the Cad, and used a crossmember running right under the motor.

Keep the good stuff comin'.

looking good motorhead.

i know all about those days you just had,lol.

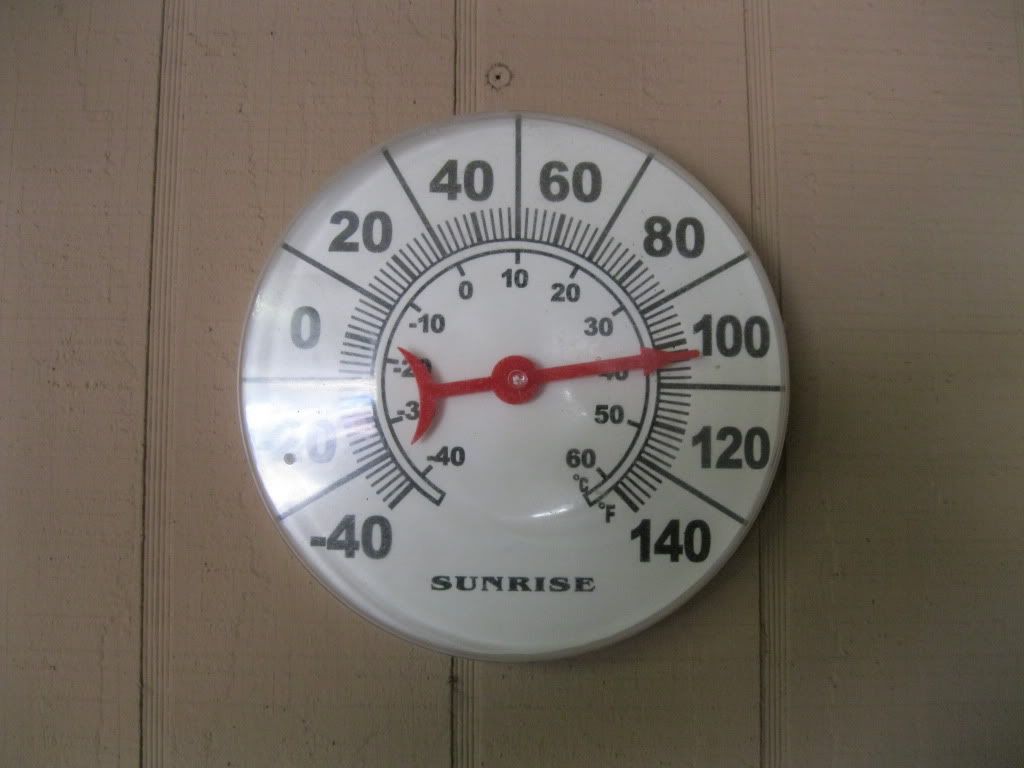

Things seem more frustrating when it's 113 and humd.

Still lookin good.

look'n good

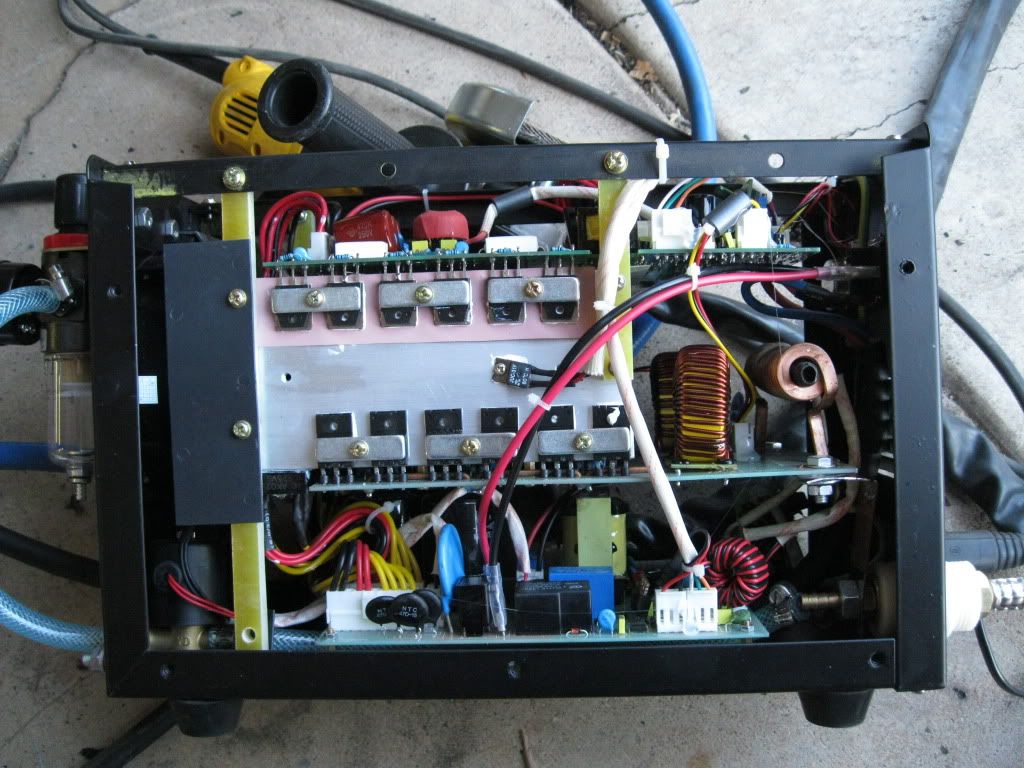

If that was my plama cutter, that hose would have been the only thing I could fix. Everything else might as well be magic.

When you start looking for a better one, check the consumables cost. I have a Lincoln Procut 80 which is a great machine, but it is more expensive to run than an oxy- acet torch. The consumbales are expensive and they don't last very long. Friends with HyperTherms and Millers say they rarely change consumables. Where do you get the consumables for that Chinese machine?

The proportions of the Dodge look very similar to my chopped F2. It doesn't have that bubble top look either. Compared to the Chevys and fords I'm used to seeing it already looks chopped. I like it.

I'd say 40 piecs for $30 is very cheap. I spend $14 per change for the consumables on the Lincoln. The average life is about 15 minutes of cutting time. I do use the drag cup whenever possible.

Waiting on the chop makes sense - you can always do it later.

Hey, I finally figured out what it is about your frame and radius rods that is so kool ! It reminds me of the Erector set I had as a kid with all the holes.... played with that for hours, always building cars and kooky machines. Training for future rat rod builders perhaps...

I agree that it looks great like it is, don’t see any need to chop it.

I’m looking forward to seeing the engine sitting in it.

I'm a little curious, are you planning on runnig a panhard bar on the front or gonna do sometnig else?

Man this one is shaping up. I see a huge affinity for roundness in your designs. "Meccano" is the keyword, as one reader mentioned.

I have a hypertherm 380 and the consumables come in a pack of 5 (5electrode, 5 caps etc) and each pack is about $19. They last me about a month or so. The CNC unit is a cutmaster 151 with a machine head and that will chew up a set of consumables in about 16 hours of cut time on 1/4". flame will start to walk around and then you know the electrode is short. But they are $100 fo 30 caps (ie 1 set of 10 ea of 20a, 40a, 80a) and 20 electrodes, and 10 shields.

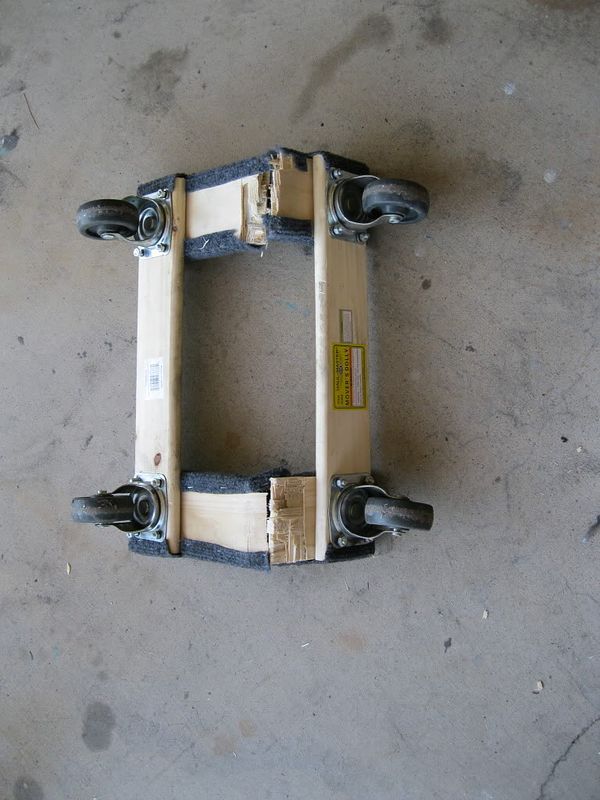

Motor mounts look good! Maybe it's time to build a metal dolly?

Motor mounts look good! Maybe it's time to build a metal dolly?

Or some pieces of box tube on the shock mounts.

Hey it cooled off today and the humidity is down, feels much better. Isn't it about time to get that window AC unit for your shop?